Otros Planetary Mills

OTROS GRUPOS DE PRODUCTOS

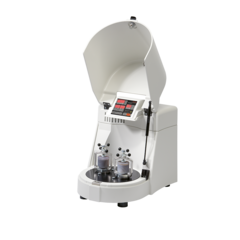

Planetary Mill

PULVERISETTE 5/4

classic linePlease note: For the Planetary Mill PULVERISETTE 5/4 classic line, you require at least 4 grinding bowls of your choice and the corresponding number of grinding balls. The grinding bowl material must also be harder than the material to be ground. In normal cases, grinding bowls and balls of the same material are used. To shorten the grinding time, larger or heavier grinding bowls and grinding balls with a higher density and correspondingly higher impact energy can be used. Please take note of the useful capacity, this is not identical with the bowl volume!

GRINDING BOWLS

-

Material data for the grinding bowls/balls

Material Main component of the material Density g/cm³ Abrasion resistance Used for grinding material Agate SiO2 2.65 good soft to medium-hard samples Sintered corundum Al2O3 (99.7%) 3.8 moderately good medium-hard, fibrous samples Silicon nitride Si3N4 3.25 extremely good abrasive samples, metal-free grinding Zirconium oxide ZrO2 5.7 very good fibrous, abrasive samples Hardened, stainless steel Fe – Cr 7.7 good hard, medium-hard, brittle samples Hardmetal tungsten carbide WC 14.3 very good hard, abrasive samples -

Recommended number of grinding balls per bowl

Grinding bowl/

Useful capacity (grinding material)80 ml

10 – 30 ml250 ml

30 – 125 ml500 ml

80 – 225 mlBalls diameter 40 mm 4 30 mm 6 8 20 mm 5 15 25 15 mm 10 45 70 10 mm 25 50 100 5 mm 250 1200 2000 Grinding balls ≤ 3 mm

Recommended ball mass per bowl in gramsGrinding bowl/

Useful capacity (grinding material)80 ml

10 – 30 ml250 ml

30 – 125 ml500 ml

80 – 225 mlZirconium oxide 100 g 400 g 800 g Hardened, stainless steel 150 g 500 g 1100 g Hard metal tungsten carbide 300 g 1000 g 2100 g -

Additional Information

Grinding balls with diameter 3 mm and smaller must be weighed out. The above table provides you with the required mass per grinding bowl.

The specified ball filling per bowl is the minimum quantity and should possibly be increased depending on the material properties. The useful capacity depends on the type of material. In exceptional cases, the number of grinding balls can be reduced by up to 15 %. However, increased abrasion should be expected. In general, smaller grinding balls achieve finer grinding results.

In normal cases, grinding bowls and balls of the same material are used. To shorten the grinding time, grinding bowls and balls with a higher density and correspondingly higher impact energy can be used.

Please select 4 grinding bowls, which are offered in the sizes 500 ml, 250 ml and 80 ml to perfectly match your sample volume. The useful capacity of the grinding bowls can be found in the selection aid. Grinding bowl 80 ml: One grinding bowl holder can be equipped with 2 bowls 80 ml or 1 bowl 80 ml using an adapter to mount the bowls on top of each other.

For the best grinding results in each individual case, all grinding bowls are available in 6 different materials, thus directly preventing contamination of the samples as a result of undesired abrasion.

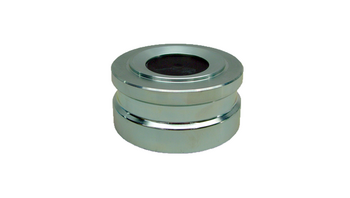

GRINDING BOWL 500 ML VOLUME

Grinding bowl with lid and seal ring

Grinding bowl volume: 500 ml

Useful capacity: 80 … 225 ml

Weight net: 3.900 kg

General material specification:

Material: agate - SiO2

Abrasion resistance: good

Suitable for: soft to medium-hard samples

Detailed information about the material you will find in the element analysis.

| General specifications | |

| Material | Agate – SiO2 |

| Chemical composition | |

| Element | Share % |

| Silicon oxide– SiO2 | 99.9 |

| Aluminium – Al2O3 | < 0.02 |

| Iron oxide – Fe2O3 | < 0.02 |

| Calcium oxide – CaO | < 0.02 |

| Magnesium oxide – MgO | < 0.02 |

| Sodium oxide – Na2O | < 0.02 |

| Potassium oxide – K2O | < 0.02 |

| Manganese oxide – MnO | < 0.02 |

| Physical and mechanical properties | |

| Density | 2.65 g/cm³ |

| Hardness | 6.5 – 7 Mohs |

Explanations on hardness data

Grinding bowl with lid and seal ring

Grinding bowl volume: 500 ml

Useful capacity: 80 … 225 ml

Weight net: 2.900 kg

General material specification:

Material: sintered corundum 1 - 99.7 % Al2O3

Abrasion resistance: fairly good

Suitable for: medium-hard, fibrous samples

Detailed information about the material you will find in the element analysis.

| General specifications | |

| Material | Sintered corundum 1 – Al2O3 |

| ISO/EN/DIN code | |

| Chemical composition | |

| Element | Share % |

| Aluminium oxide – Al2O3 | 99.651 |

| Silicon oxide – SiO2 | 0.257 |

| Calcium oxide – CaO | 0.081 |

| Other | 0.011 |

| Physical and mechanical properties | |

| Density | 3.8 g/cm³ |

| Hardness | 18.000N/mm² (Vickers HV 0.5) |

Explanations on hardness data

Grinding bowl with lid and seal ring

Grinding bowl volume: 500 ml

Useful capacity: 80 … 225 ml

Weight net: 3.400 kg

General material specification:

Material: silicon nitride - Si3N4

Abrasion resistance: excellent

Suitable for: abrasive samples, metal-free grinding

Detailed information about the material you will find in the element analysis.

| General specifications | |

| Material | Silicon nitride - Si3N4 |

| ISO/EN/DIN code | SNCB5 |

| Chemical composition | |

| Element | Share % |

| Al2 O3 Y2 O3 | 9 |

| Si3 N4 | 91 |

| Physical and mechanical properties | |

| Density | 3.25 g/cm³ |

| Hardness | 91.1 HRA |

Explanations on hardness data

Grinding bowl with lid and seal ring

Grinding bowl volume: 500 ml

Useful capacity: 80 … 225 ml

Weight net: 4.000 kg

General material specification:

Material: zirconium oxide - ZrO2

Abrasion resistance: very good

Suitable for: fibrous, abrasive samples

Detailed information about the material you will find in the element analysis.

| General specifications | |

| Material | Zirconium oxide - ZrO2 |

| Chemical composition | |

| Element | Share % |

| Zirconium oxide – ZrO2 | 94.2 - 95.2 |

| Hafnium oxide – HfO2 | 1 - 2 |

| Magnesium oxide – MgO | 3.5 |

| Silicon dioxide – SiO | 0.1 |

| Aluminium oxide – Al2O3 | 0.1 |

| Other | 0.1 |

| Physical and mechanical properties | |

| Density | 5.7 g/cm³ |

| Hardness Vickers | 1200 (HV10) |

Explanations on hardness data

Grinding bowl with lid and seal ring

Grinding bowl volume: 500 ml

Useful capacity: 80 … 225 ml

Weight net: 4.300 kg

General material specification:

Material: hardened, stainless steel - Fe-Cr

Abrasion resistance: good

Suitable for: hard, medium-hard, brittle samples

Detailed information about the material you will find in the element analysis.

| General specifications | |

| Material | hardened stainless steel – 1.4125 |

| ISO/EN/DIN code | X105CrMo17 |

| Chemical composition | |

| Element | Share % |

| Iron– Fe | 81.4 |

| Chromium – Cr | 17 |

| Carbon – C | 1.1 |

| Molybdenum – Mo | 0.5 |

| Physical and mechanical properties | |

| Density | 7.7 kg/dm³ |

| Hardness | ~ 60 HRC |

Explanations on hardness data

REPLACEMENT SEAL RING PTFE FOR GRINDING BOWLS 500 ML VOLUME

Replacement seal ring made of PTFE, 121/110 mm dia. for agate grinding bowls of 500 ml volume.

Replacement seal ring made of PTFE, 110/101 mm dia. for silicon nitride grinding bowls of 500 ml volume.

| General specifications | |

| Material | PTFE |

| CAS Number | 9002-84-0 |

| Chemical composition | ||||

| Element | Formula | |||

| Polytetrafluoroethylene | C 2F4 | |||

| Melting point | 327° C | |||

| Max. application temp. constant | 260° C | |||

| Max. application temp. briefly | 300° C | |||

| Physical and mechanical properties | |

| Density | 2.16 g /cm³ |

| Ball pressure hardness | ISO 868, ISO 2039-2, D 55 Shore |

Replacement seal ring PTFE, 116/100 mm dia. for all other grinding bowls 500 ml volume, except silicon nitride and agate.

| General specifications | |

| Material | PTFE |

| CAS Number | 9002-84-0 |

| Chemical composition | ||||

| Element | Formula | |||

| Polytetrafluoroethylene | C 2F4 | |||

| Melting point | 327° C | |||

| Max. application temp. constant | 260° C | |||

| Max. application temp. briefly | 300° C | |||

| Physical and mechanical properties | |

| Density | 2.16 g /cm³ |

| Ball pressure hardness | ISO 868, ISO 2039-2, D 55 Shore |

GRINDING BOWL 250 ML VOLUME

Grinding bowl with lid and seal ring

Grinding bowl volume: 250 ml

Useful capacity: 30 … 125 ml

Weight net: 2.500 kg

General material specification:

Material: agate - SiO2

Abrasion resistance: good

Suitable for: soft to medium-hard samples

Detailed information about the material you will find in the element analysis.

| General specifications | |

| Material | Agate – SiO2 |

| Chemical composition | |

| Element | Share % |

| Silicon oxide– SiO2 | 99.9 |

| Aluminium – Al2O3 | < 0.02 |

| Iron oxide – Fe2O3 | < 0.02 |

| Calcium oxide – CaO | < 0.02 |

| Magnesium oxide – MgO | < 0.02 |

| Sodium oxide – Na2O | < 0.02 |

| Potassium oxide – K2O | < 0.02 |

| Manganese oxide – MnO | < 0.02 |

| Physical and mechanical properties | |

| Density | 2.65 g/cm³ |

| Hardness | 6.5 – 7 Mohs |

Explanations on hardness data

Grinding bowl with lid and seal ring

Grinding bowl volume: 250 ml

Useful capacity: 30 … 125 ml

Weight net: 2.300 kg

General material specification:

Material: sintered corundum 1 - 99.7 % Al2O3

Abrasion resistance: fairly good

Suitable for: medium-hard, fibrous samples

Detailed information about the material you will find in the element analysis.

| General specifications | |

| Material | Sintered corundum 1 – Al2O3 |

| ISO/EN/DIN code | |

| Chemical composition | |

| Element | Share % |

| Aluminium oxide – Al2O3 | 99.651 |

| Silicon oxide – SiO2 | 0.257 |

| Calcium oxide – CaO | 0.081 |

| Other | 0.011 |

| Physical and mechanical properties | |

| Density | 3.8 g/cm³ |

| Hardness | 18.000N/mm² (Vickers HV 0.5) |

Explanations on hardness data

Grinding bowl with lid and seal ring

Grinding bowl volume: 250 ml

Useful capacity: 30 … 125 ml

Weight net: 2.800 kg

General material specification:

Material: silicon nitride - Si3N4

Abrasion resistance: excellent

Suitable for: abrasive samples, metal-free grinding

Detailed information about the material you will find in the element analysis.

| General specifications | |

| Material | Silicon nitride - Si3N4 |

| ISO/EN/DIN code | SNCB5 |

| Chemical composition | |

| Element | Share % |

| Al2 O3 Y2 O3 | 9 |

| Si3 N4 | 91 |

| Physical and mechanical properties | |

| Density | 3.25 g/cm³ |

| Hardness | 91.1 HRA |

Explanations on hardness data

Grinding bowl with lid and seal ring

Grinding bowl volume: 250 ml

Useful capacity: 30 … 125 ml

Weight net: 3.100 kg

General material specification:

Material: zirconium oxide - ZrO2

Abrasion resistance: very good

Suitable for: fibrous, abrasive samples

Detailed information about the material you will find in the element analysis.

| General specifications | |

| Material | Zirconium oxide - ZrO2 |

| Chemical composition | |

| Element | Share % |

| Zirconium oxide – ZrO2 | 94.2 - 95.2 |

| Hafnium oxide – HfO2 | 1 - 2 |

| Magnesium oxide – MgO | 3.5 |

| Silicon dioxide – SiO | 0.1 |

| Aluminium oxide – Al2O3 | 0.1 |

| Other | 0.1 |

| Physical and mechanical properties | |

| Density | 5.7 g/cm³ |

| Hardness Vickers | 1200 (HV10) |

Explanations on hardness data

Grinding bowl with lid and seal ring

Grinding bowl volume: 250 ml

Useful capacity: 30 … 125 ml

Weight net: 3.200 kg

General material specification:

Material: hardened, stainless steel - Fe-Cr

Abrasion resistance: good

Suitable for: hard, medium-hard, brittle samples

Detailed information about the material you will find in the element analysis.

| General specifications | |

| Material | hardened stainless steel – 1.4125 |

| ISO/EN/DIN code | X105CrMo17 |

| Chemical composition | |

| Element | Share % |

| Iron– Fe | 81.4 |

| Chromium – Cr | 17 |

| Carbon – C | 1.1 |

| Molybdenum – Mo | 0.5 |

| Physical and mechanical properties | |

| Density | 7.7 kg/dm³ |

| Hardness | ~ 60 HRC |

Explanations on hardness data

Grinding bowl with lid and seal ring

Grinding bowl volume: 250 ml

Useful capacity: 30 … 125 ml

Weight net: 5.000 kg

General material specification:

Material: hardmetal tungsten carbide - WC

Abrasion resistance: very good

Suitable for: hard, abrasive samples

Detailed information about the material you will find in the element analysis.

| General specifications | |

| Material | Tungsten carbide - WC |

| ISO/EN/DIN code | |

| Chemical composition | |

| Element | Share % |

| Tungsten carbide – TC | 88 |

| Cobalt – Co | 12 |

| Physical and mechanical properties | |

| Density | 14.3 g/cm³ |

| Hardness | 89.7 HRA |

Explanations on hardness data

REPLACEMENT SEAL RING PTFE FOR GRINDING BOWLS 250 ML VOLUME

Replacement seal ring PTFE 85/70 mm dia. for agate grinding bowls of 80 + 250 ml volume.

| General specifications | |

| Material | PTFE |

| CAS Number | 9002-84-0 |

| Chemical composition | ||||

| Element | Formula | |||

| Polytetrafluoroethylene | C 2F4 | |||

| Melting point | 327° C | |||

| Max. application temp. constant | 260° C | |||

| Max. application temp. briefly | 300° C | |||

| Physical and mechanical properties | |

| Density | 2.16 g /cm³ |

| Ball pressure hardness | ISO 868, ISO 2039-2, D 55 Shore |

Replacement seal ring PTFE for 85/76 mm dia. for silicon nitride grinding bowls of 250 ml volume.

| General specifications | |

| Material | PTFE |

| CAS Number | 9002-84-0 |

| Chemical composition | ||||

| Element | Formula | |||

| Polytetrafluoroethylene | C 2F4 | |||

| Melting point | 327° C | |||

| Max. application temp. constant | 260° C | |||

| Max. application temp. briefly | 300° C | |||

| Physical and mechanical properties | |

| Density | 2.16 g /cm³ |

| Ball pressure hardness | ISO 868, ISO 2039-2, D 55 Shore |

Replacement seal ring made of PTFE, 90/75 mm dia., for all other grinding bowls, 250 ml volume, except agate and silicon Nitride.

| General specifications | |

| Material | PTFE |

| CAS Number | 9002-84-0 |

| Chemical composition | ||||

| Element | Formula | |||

| Polytetrafluoroethylene | C 2F4 | |||

| Melting point | 327° C | |||

| Max. application temp. constant | 260° C | |||

| Max. application temp. briefly | 300° C | |||

| Physical and mechanical properties | |

| Density | 2.16 g /cm³ |

| Ball pressure hardness | ISO 868, ISO 2039-2, D 55 Shore |

GRINDING BOWL 80 ML VOLUME

Grinding bowl with lid and seal ring

Grinding bowl volume: 80 ml

Useful capacity: 10 … 30

Weight net: 1.550 kg

General material specification:

Material: agate - SiO2

Abrasion resistance: good

Suitable for: soft to medium-hard samples

Detailed information about the material you will find in the element analysis.

| General specifications | |

| Material | Agate – SiO2 |

| Chemical composition | |

| Element | Share % |

| Silicon oxide– SiO2 | 99.9 |

| Aluminium – Al2O3 | < 0.02 |

| Iron oxide – Fe2O3 | < 0.02 |

| Calcium oxide – CaO | < 0.02 |

| Magnesium oxide – MgO | < 0.02 |

| Sodium oxide – Na2O | < 0.02 |

| Potassium oxide – K2O | < 0.02 |

| Manganese oxide – MnO | < 0.02 |

| Physical and mechanical properties | |

| Density | 2.65 g/cm³ |

| Hardness | 6.5 – 7 Mohs |

Explanations on hardness data

Grinding bowl with lid and seal ring

Grinding bowl volume: 80 ml

Useful capacity: 10 … 30 ml

Weight net: 1.000 kg

General material specification:

Material: sintered corundum 1 - 99.7 % Al2O3

Abrasion resistance: fairly good

Suitable for: medium-hard, fibrous samples

Detailed information about the material you will find in the element analysis.

| General specifications | |

| Material | Sintered corundum 1 – Al2O3 |

| ISO/EN/DIN code | |

| Chemical composition | |

| Element | Share % |

| Aluminium oxide – Al2O3 | 99.651 |

| Silicon oxide – SiO2 | 0.257 |

| Calcium oxide – CaO | 0.081 |

| Other | 0.011 |

| Physical and mechanical properties | |

| Density | 3.8 g/cm³ |

| Hardness | 18.000N/mm² (Vickers HV 0.5) |

Explanations on hardness data

Grinding bowl with lid and seal ring

Grinding bowl volume: 80 ml

Useful capacity: 10 … 30 ml

Weight net: 0.800 kg

General material specification:

Material: silicon nitride - Si3N4

Abrasion resistance: excellent

Suitable for: abrasive samples, metal-free grinding

Detailed information about the material you will find in the element analysis.

| General specifications | |

| Material | Silicon nitride - Si3N4 |

| ISO/EN/DIN code | SNCB5 |

| Chemical composition | |

| Element | Share % |

| Al2 O3 Y2 O3 | 9 |

| Si3 N4 | 91 |

| Physical and mechanical properties | |

| Density | 3.25 g/cm³ |

| Hardness | 91.1 HRA |

Explanations on hardness data

Grinding bowl with lid and seal ring

Grinding bowl volume: 80 ml

Useful capacity: 10 … 30 ml

Weight net: 1.400 kg

General material specification:

Material: zirconium oxide - ZrO2

Abrasion resistance: very good

Suitable for: fibrous, abrasive samples

Detailed information about the material you will find in the element analysis.

| General specifications | |

| Material | Zirconium oxide - ZrO2 |

| Chemical composition | |

| Element | Share % |

| Zirconium oxide – ZrO2 | 94.2 - 95.2 |

| Hafnium oxide – HfO2 | 1 - 2 |

| Magnesium oxide – MgO | 3.5 |

| Silicon dioxide – SiO | 0.1 |

| Aluminium oxide – Al2O3 | 0.1 |

| Other | 0.1 |

| Physical and mechanical properties | |

| Density | 5.7 g/cm³ |

| Hardness Vickers | 1200 (HV10) |

Explanations on hardness data

Grinding bowl with lid and seal ring

Grinding bowl volume: 80 ml

Useful capacity: 10 … 30 ml

Weight net: 1.900 kg

General material specification:

Material: hardened, stainless steel - Fe-Cr

Abrasion resistance: good

Suitable for: hard, medium-hard, brittle samples

Detailed information about the material you will find in the element analysis.

| General specifications | |

| Material | hardened stainless steel – 1.4125 |

| ISO/EN/DIN code | X105CrMo17 |

| Chemical composition | |

| Element | Share % |

| Iron– Fe | 81.4 |

| Chromium – Cr | 17 |

| Carbon – C | 1.1 |

| Molybdenum – Mo | 0.5 |

| Physical and mechanical properties | |

| Density | 7.7 kg/dm³ |

| Hardness | ~ 60 HRC |

Explanations on hardness data

Grinding bowl with lid and seal ring

Grinding bowl volume: 80 ml

Useful capacity: 10 … 30 ml

Weight net: 2.400 kg

General material specification:

Material: hardmetal tungsten carbide - WC

Abrasion resistance: very good

Suitable for: hard, abrasive samples

Detailed information about the material you will find in the element analysis.

| General specifications | |

| Material | Tungsten carbide - WC |

| ISO/EN/DIN code | |

| Chemical composition | |

| Element | Share % |

| Tungsten carbide – TC | 88 |

| Cobalt – Co | 12 |

| Physical and mechanical properties | |

| Density | 14.3 g/cm³ |

| Hardness | 89.7 HRA |

Explanations on hardness data

REPLACEMENT SEAL RING PTFE FOR GRINDING BOWLS 80 ML VOLUME AND ADAPTER

Replacement seal ring PTFE 85/70 mm dia. for agate grinding bowls of 80 + 250 ml volume.

| General specifications | |

| Material | PTFE |

| CAS Number | 9002-84-0 |

| Chemical composition | ||||

| Element | Formula | |||

| Polytetrafluoroethylene | C 2F4 | |||

| Melting point | 327° C | |||

| Max. application temp. constant | 260° C | |||

| Max. application temp. briefly | 300° C | |||

| Physical and mechanical properties | |

| Density | 2.16 g /cm³ |

| Ball pressure hardness | ISO 868, ISO 2039-2, D 55 Shore |

Replacement seal ring made of PTFE, 80/65 mm dia. for all other grinding bowls 80 ml volume.

| General specifications | |

| Material | PTFE |

| CAS Number | 9002-84-0 |

| Chemical composition | ||||

| Element | Formula | |||

| Polytetrafluoroethylene | C 2F4 | |||

| Melting point | 327° C | |||

| Max. application temp. constant | 260° C | |||

| Max. application temp. briefly | 300° C | |||

| Physical and mechanical properties | |

| Density | 2.16 g /cm³ |

| Ball pressure hardness | ISO 868, ISO 2039-2, D 55 Shore |

If only one grinding bowl of 12, 45 or 80 ml volume per grinding bowl holder is inserted in the PULVERISETTE 5 or PULVERISETTE 6 classic line, this adapter is essential as adjustment.

GRINDING BOWL 45 ML VOLUME

Grinding bowl with lid and seal ring

Grinding bowl volume: 45 ml

Useful capacity: 3 … 20 ml

Weight net: 0.300 kg

General material specification:

Material: agate - SiO2

Abrasion resistance: good

Suitable for: soft to medium-hard samples

Detailed information about the material you will find in the element analysis.

| General specifications | |

| Material | Agate – SiO2 |

| Chemical composition | |

| Element | Share % |

| Silicon oxide– SiO2 | 99.9 |

| Aluminium – Al2O3 | < 0.02 |

| Iron oxide – Fe2O3 | < 0.02 |

| Calcium oxide – CaO | < 0.02 |

| Magnesium oxide – MgO | < 0.02 |

| Sodium oxide – Na2O | < 0.02 |

| Potassium oxide – K2O | < 0.02 |

| Manganese oxide – MnO | < 0.02 |

| Physical and mechanical properties | |

| Density | 2.65 g/cm³ |

| Hardness | 6.5 – 7 Mohs |

Explanations on hardness data

Grinding bowl with lid and seal ring

Grinding bowl volume: 45 ml

Useful capacity: 3 … 20 ml

Weight net: 0.350 kg

General material specification:

Material: sintered corundum 1 - 99.7 % Al2O3

Abrasion resistance: fairly good

Suitable for: medium-hard, fibrous samples

Detailed information about the material you will find in the element analysis.

| General specifications | |

| Material | Sintered corundum 1 – Al2O3 |

| ISO/EN/DIN code | |

| Chemical composition | |

| Element | Share % |

| Aluminium oxide – Al2O3 | 99.651 |

| Silicon oxide – SiO2 | 0.257 |

| Calcium oxide – CaO | 0.081 |

| Other | 0.011 |

| Physical and mechanical properties | |

| Density | 3.8 g/cm³ |

| Hardness | 18.000N/mm² (Vickers HV 0.5) |

Explanations on hardness data

Grinding bowl with lid and seal ring

Grinding bowl volume: 45 ml

Useful capacity: 3 … 20 ml

Weight net: 0.500 kg

General material specification:

Material: zirconium oxide - ZrO2

Abrasion resistance: very good

Suitable for: fibrous, abrasive samples

Detailed information about the material you will find in the element analysis.

| General specifications | |

| Material | Zirconium oxide - ZrO2 |

| Chemical composition | |

| Element | Share % |

| Zirconium oxide – ZrO2 | 94.2 - 95.2 |

| Hafnium oxide – HfO2 | 1 - 2 |

| Magnesium oxide – MgO | 3.5 |

| Silicon dioxide – SiO | 0.1 |

| Aluminium oxide – Al2O3 | 0.1 |

| Other | 0.1 |

| Physical and mechanical properties | |

| Density | 5.7 g/cm³ |

| Hardness Vickers | 1200 (HV10) |

Explanations on hardness data

Grinding bowl with lid and seal ring

Grinding bowl volume: 45 ml

Useful capacity: 3 … 20 ml

Weight net: 0.700 kg

General material specification:

Material: hardened, stainless steel - Fe-Cr

Abrasion resistance: good

Suitable for: hard, medium-hard, brittle samples

Detailed information about the material you will find in the element analysis.

| General specifications | |

| Material | hardened stainless steel – 1.4125 |

| ISO/EN/DIN code | X105CrMo17 |

| Chemical composition | |

| Element | Share % |

| Iron– Fe | 81.4 |

| Chromium – Cr | 17 |

| Carbon – C | 1.1 |

| Molybdenum – Mo | 0.5 |

| Physical and mechanical properties | |

| Density | 7.7 kg/dm³ |

| Hardness | ~ 60 HRC |

Explanations on hardness data

Grinding bowl with lid and seal ring

Grinding bowl volume: 45 ml

Useful capacity: 3 … 20 ml

Weight net: 1.100 kg

General material specification:

Material: hardmetal tungsten carbide - WC

Abrasion resistance: very good

Suitable for: hard, abrasive samples

Detailed information about the material you will find in the element analysis.

| General specifications | |

| Material | Tungsten carbide - WC |

| ISO/EN/DIN code | |

| Chemical composition | |

| Element | Share % |

| Tungsten carbide – TC | 93.8 |

| Cobalt – Co | 6.0 |

| Other | 0.2 |

| Physical and mechanical properties | |

| Density | 14.95 g/cm³ |

| Hardness | 92.1 HRA |

Explanations on hardness data

Grinding bowl with lid and seal ring

Grinding bowl volume: 45 ml

Useful capacity: 3 … 20 ml

Weight net: 0.350 kg

General material specification:

Material: silicon nitride - Si3N4

Abrasion resistance: excellent

Suitable for: abrasive samples, metal-free grinding

Detailed information about the material you will find in the element analysis.

| General specifications | |

| Material | Silicon nitride - Si3N4 |

| ISO/EN/DIN code | SNCB5 |

| Chemical composition | |

| Element | Share % |

| Al2 O3 Y2 O3 | 9 |

| Si3 N4 | 91 |

| Physical and mechanical properties | |

| Density | 3.25 g/cm³ |

| Hardness | 91.1 HRA |

Explanations on hardness data

Disposable bowl with screw lid

Grinding bowl volume: 45 ml

Useful capacity: 3 … 20 ml

Weight net: 0.013

General material specification:

Material: polypropylene - PP

Suitable for: homogenisation

Density: 0.895 - 0.92 g/cm³

REPLACEMENT SEAL RING PTFE FOR GRINDING BOWLS 45 ML VOLUME

Replacement seal ring made of PTFE, 50/40 mm dia. for all grinding bowls 45 ml volume.

| General specifications | |

| Material | PTFE |

| CAS Number | 9002-84-0 |

| Chemical composition | ||||

| Element | Formula | |||

| Polytetrafluoroethylene | C 2F4 | |||

| Melting point | 327° C | |||

| Max. application temp. constant | 260° C | |||

| Max. application temp. briefly | 300° C | |||

| Physical and mechanical properties | |

| Density | 2.16 g /cm³ |

| Ball pressure hardness | ISO 868, ISO 2039-2, D 55 Shore |

GRINDING BALLS

-

Material data for the grinding bowls/balls

Material Main component of the material Density g/cm³ Abrasion resistance Used for grinding material Agate SiO2 2.65 good soft to medium-hard samples Sintered corundum Al2O3 (99.7%) 3.8 moderately good medium-hard, fibrous samples Silicon nitride Si3N4 3.25 extremely good abrasive samples, metal-free grinding Zirconium oxide ZrO2 5.7 very good fibrous, abrasive samples Hardened, stainless steel Fe – Cr 7.7 good hard, medium-hard, brittle samples Hardmetal tungsten carbide WC 14.3 very good hard, abrasive samples -

Recommended grinding ball size

Kind of application Suitable grinding ball diameter Maximum feed size of 10 mm 30 mm or 40 mm Average feed size of ≤ 5 mm 20 mm, 15 mm or 10 mm Fine material < 0.5 mm 10 mm or smaller Homogenisation of dry or liquid samples 20 mm or smaller Homogenisation of viscous samples 20 mm The specified grinding ball sizes are application-dependent reference values. It is not recommended to mix balls of different diameters. Grinding balls with a diameter of 40 mm should only be used for a short grinding time. -

Recommended number of grinding balls per bowl

Grinding bowl/

Useful capacity (grinding material)80 ml

10 – 30 ml250 ml

30 – 125 ml500 ml

80 – 225 mlBalls diameter 40 mm 4 30 mm 6 8 20 mm 5 15 25 15 mm 10 45 70 10 mm 25 50 100 5 mm 250 1200 2000 Grinding balls ≤ 3 mm

Recommended ball mass per bowl in gramsGrinding bowl/

Useful capacity (grinding material)80 ml

10 – 30 ml250 ml

30 – 125 ml500 ml

80 – 225 mlZirconium oxide 100 g 400 g 800 g Hardened, stainless steel 150 g 500 g 1100 g Hard metal tungsten carbide 300 g 1000 g 2100 g -

Additional Information

Grinding balls with diameter 3 mm and smaller must be weighed out. The above table provides you with the required mass per grinding bowl.

The specified ball filling per bowl is the minimum quantity and should possibly be increased depending on the material properties. The useful capacity depends on the type of material. In exceptional cases, the number of grinding balls can be reduced by up to 15 %. However, increased abrasion should be expected. In general, smaller grinding balls achieve finer grinding results.

In normal cases, grinding bowls and balls of the same material are used. To shorten the grinding time, grinding bowls and balls with a higher density and correspondingly higher impact energy can be used.

For achieving best grinding results grinding balls are available in 0.1 - 40 mm diameters and in 6 different materials, thus directly preventing contamination of the samples as a result of undesired abrasion. The recommended number of balls per grinding bowl can be found in the selection aid.

GRINDING BALLS 40 MM DIAMETER FOR GRINDING BOWL 500 ML

General material specification:

Material: sintered corundum 1 - 99.7 % Al2O3

Abrasion resistance: fairly good

Suitable for: medium-hard, fibrous samples

| General specifications | |

| Material | Sintered corundum 1 – Al2O3 |

| ISO/EN/DIN code | |

| Chemical composition | |

| Element | Share % |

| Aluminium oxide – Al2O3 | 99.651 |

| Silicon oxide – SiO2 | 0.257 |

| Calcium oxide – CaO | 0.081 |

| Other | 0.011 |

| Physical and mechanical properties | |

| Density | 3.8 g/cm³ |

| Hardness | 18.000N/mm² (Vickers HV 0.5) |

Explanations on hardness data

General material specification:

Material: silicon nitride - Si3N4

Abrasion resistance: excellent

Suitable for: abrasive samples, metal-free grinding

| General specifications | |

| Material | Silicon nitride - Si3N4 |

| ISO/EN/DIN code | SNCB5 |

| Chemical composition | |

| Element | Share % |

| Al2 O3 Y2 O3 | 12.5 |

| Si3 N4 | 86.5 |

| Other | 1.00 |

| Physical and mechanical properties | |

| Density | 3.25 g/cm³ |

| Hardness | 91.1 HRA |

Explanations on hardness data

General material specification:

Material: zirconium oxide - ZrO2

Abrasion resistance: very good

Suitable for: fibrous, abrasive samples

| General specifications | |

| Material | Zirconium oxide - ZrO2 |

| Chemical composition | |

| Element | Share % |

| Zirconium oxide – ZrO2 | 94.2 - 95.2 |

| Hafnium oxide – HfO2 | 1 - 2 |

| Magnesium oxide – MgO | 3.5 |

| Silicon dioxide – SiO | 0.1 |

| Aluminium oxide – Al2O3 | 0.1 |

| Other | 0.1 |

| Physical and mechanical properties | |

| Density | 5.7 g/cm³ |

| Hardness Vickers | 1200 (HV10) |

Explanations on hardness data

General material specification:

Material: hardened, stainless steel - Fe-Cr

Abrasion resistance: good

Suitable for: hard, medium-hard, brittle samples

| General specifications | |

| Material | hardened stainless steel – 1.4125 |

| ISO/EN/DIN code | X105CrMo17 |

| Chemical composition | |

| Element | Share % |

| Iron– Fe | 81.4 |

| Chromium – Cr | 17 |

| Carbon – C | 1.1 |

| Molybdenum – Mo | 0.5 |

| Physical and mechanical properties | |

| Density | 7.7 kg/dm³ |

| Hardness | ~ 60 HRC |

Explanations on hardness data

GRINDING BALLS 30 MM DIAMETER FOR GRINDING BOWL 500 ML, 250 ML

General material specification:

Material: agate - SiO2

Abrasion resistance: good

Suitable for: soft to medium-hard sample

| General specifications | |

| Material | Agate – SiO2 |

| Chemical composition | |

| Element | Share % |

| Silicon oxide– SiO2 | 99.9 |

| Aluminium – Al2O3 | < 0.02 |

| Iron oxide – Fe2O3 | < 0.02 |

| Calcium oxide – CaO | < 0.02 |

| Magnesium oxide – MgO | < 0.02 |

| Sodium oxide – Na2O | < 0.02 |

| Potassium oxide – K2O | < 0.02 |

| Manganese oxide – MnO | < 0.02 |

| Physical and mechanical properties | |

| Density | 2.65 g/cm³ |

| Hardness | 6.5 – 7 Mohs |

Explanations on hardness data

General material specification:

Material: sintered corundum 1 - 99.7 % Al2O3

Abrasion resistance: fairly good

Suitable for: medium-hard, fibrous samples

| General specifications | |

| Material | Sintered corundum 1 – Al2O3 |

| ISO/EN/DIN code | |

| Chemical composition | |

| Element | Share % |

| Aluminium oxide – Al2O3 | 99.651 |

| Silicon oxide – SiO2 | 0.257 |

| Calcium oxide – CaO | 0.081 |

| Other | 0.011 |

| Physical and mechanical properties | |

| Density | 3.8 g/cm³ |

| Hardness | 18.000N/mm² (Vickers HV 0.5) |

Explanations on hardness data

General material specification:

Material: silicon nitride - Si3N4

Abrasion resistance: excellent

Suitable for: abrasive samples, metal-free grinding

| General specifications | |

| Material | Silicon nitride - Si3N4 |

| ISO/EN/DIN code | SNCB5 |

| Chemical composition | |

| Element | Share % |

| Al2 O3 Y2 O3 | 12.5 |

| Si3 N4 | 86.5 |

| Other | 1.00 |

| Physical and mechanical properties | |

| Density | 3.25 g/cm³ |

| Hardness | 91.1 HRA |

Explanations on hardness data

General material specification:

Material: zirconium oxide - ZrO2

Abrasion resistance: very good

Suitable for: fibrous, abrasive samples

| General specifications | |

| Material | Zirconium oxide - ZrO2 |

| Chemical composition | |

| Element | Share % |

| Zirconium oxide – ZrO2 | 94.2 - 95.2 |

| Hafnium oxide – HfO2 | 1 - 2 |

| Magnesium oxide – MgO | 3.5 |

| Silicon dioxide – SiO | 0.1 |

| Aluminium oxide – Al2O3 | 0.1 |

| Other | 0.1 |

| Physical and mechanical properties | |

| Density | 5.7 g/cm³ |

| Hardness Vickers | 1200 (HV10) |

Explanations on hardness data

General material specification:

Material: hardened, stainless steel - Fe-Cr

Abrasion resistance: good

Suitable for: hard, medium-hard, brittle samples

| General specifications | |

| Material | hardened stainless steel – 1.4125 |

| ISO/EN/DIN code | X105CrMo17 |

| Chemical composition | |

| Element | Share % |

| Iron– Fe | 81.4 |

| Chromium – Cr | 17 |

| Carbon – C | 1.1 |

| Molybdenum – Mo | 0.5 |

| Physical and mechanical properties | |

| Density | 7.7 kg/dm³ |

| Hardness | ~ 60 HRC |

Explanations on hardness data

General material specification:

Material: hardmetal tungsten carbide - WC

Abrasion resistance: very good

Suitable for: hard, abrasive samples

| General specifications | |

| Material | Tungsten carbide - WC |

| ISO/EN/DIN code | |

| Chemical composition | |

| Element | Share % |

| Tungsten carbide – TC | 88 |

| Cobalt – Co | 12 |

| Physical and mechanical properties | |

| Density | 14.3 g/cm³ |

| Hardness | 89.7 HRA |

Explanations on hardness data

GRINDING BALLS 20 MM DIAMETER FOR GRINDING BOWL 500 ML, 250 ML, 80 ML

General material specification:

Material: agate - SiO2

Abrasion resistance: good

Suitable for: soft to medium-hard sample

| General specifications | |

| Material | Agate – SiO2 |

| Chemical composition | |

| Element | Share % |

| Silicon oxide– SiO2 | 99.9 |

| Aluminium – Al2O3 | < 0.02 |

| Iron oxide – Fe2O3 | < 0.02 |

| Calcium oxide – CaO | < 0.02 |

| Magnesium oxide – MgO | < 0.02 |

| Sodium oxide – Na2O | < 0.02 |

| Potassium oxide – K2O | < 0.02 |

| Manganese oxide – MnO | < 0.02 |

| Physical and mechanical properties | |

| Density | 2.65 g/cm³ |

| Hardness | 6.5 – 7 Mohs |

Explanations on hardness data

General material specification:

Material: sintered corundum 1 - 99.7 % Al2O3

Abrasion resistance: fairly good

Suitable for: medium-hard, fibrous samples

| General specifications | |

| Material | Sintered corundum 1 – Al2O3 |

| ISO/EN/DIN code | |

| Chemical composition | |

| Element | Share % |

| Aluminium oxide – Al2O3 | 99.651 |

| Silicon oxide – SiO2 | 0.257 |

| Calcium oxide – CaO | 0.081 |

| Other | 0.011 |

| Physical and mechanical properties | |

| Density | 3.8 g/cm³ |

| Hardness | 18.000N/mm² (Vickers HV 0.5) |

Explanations on hardness data

General material specification:

Material: silicon nitride - Si3N4

Abrasion resistance: excellent

Suitable for: abrasive samples, metal-free grinding

| General specifications | |

| Material | Silicon nitride - Si3N4 |

| ISO/EN/DIN code | SNCB5 |

| Chemical composition | |

| Element | Share % |

| Al2 O3 Y2 O3 | 12.5 |

| Si3 N4 | 86.5 |

| Other | 1.00 |

| Physical and mechanical properties | |

| Density | 3.25 g/cm³ |

| Hardness | 91.1 HRA |

Explanations on hardness data

General material specification:

Material: zirconium oxide - ZrO2

Abrasion resistance: very good

Suitable for: fibrous, abrasive samples

| General specifications | |

| Material | Zirconium oxide - ZrO2 |

| Chemical composition | |

| Element | Share % |

| Zirconium oxide – ZrO2 | 94.2 - 95.2 |

| Hafnium oxide – HfO2 | 1 - 2 |

| Magnesium oxide – MgO | 3.5 |

| Silicon dioxide – SiO | 0.1 |

| Aluminium oxide – Al2O3 | 0.1 |

| Other | 0.1 |

| Physical and mechanical properties | |

| Density | 5.7 g/cm³ |

| Hardness Vickers | 1200 (HV10) |

Explanations on hardness data

General material specification:

Material: hardened, stainless steel - Fe-Cr

Abrasion resistance: good

Suitable for: hard, medium-hard, brittle samples

| General specifications | |

| Material | hardened stainless steel – 1.4125 |

| ISO/EN/DIN code | X105CrMo17 |

| Chemical composition | |

| Element | Share % |

| Iron– Fe | 81.4 |

| Chromium – Cr | 17 |

| Carbon – C | 1.1 |

| Molybdenum – Mo | 0.5 |

| Physical and mechanical properties | |

| Density | 7.7 kg/dm³ |

| Hardness | ~ 60 HRC |

Explanations on hardness data

General material specification:

Material: hardmetal tungsten carbide - WC

Abrasion resistance: very good

Suitable for: hard, abrasive samples

| General specifications | |

| Material | Tungsten carbide - WC |

| ISO/EN/DIN code | |

| Chemical composition | |

| Element | Share % |

| Tungsten carbide – TC | 88 |

| Cobalt – Co | 12 |

| Physical and mechanical properties | |

| Density | 14.3 g/cm³ |

| Hardness | 89.7 HRA |

Explanations on hardness data

GRINDING BALLS 15 MM DIAMETER FOR GRINDING BOWL 500 ML, 250 ML, 80 ML

General material specification:

Material: agate - SiO2

Abrasion resistance: good

Suitable for: soft to medium-hard sample

| General specifications | |

| Material | Agate – SiO2 |

| Chemical composition | |

| Element | Share % |

| Silicon oxide– SiO2 | 99.9 |

| Aluminium – Al2O3 | < 0.02 |

| Iron oxide – Fe2O3 | < 0.02 |

| Calcium oxide – CaO | < 0.02 |

| Magnesium oxide – MgO | < 0.02 |

| Sodium oxide – Na2O | < 0.02 |

| Potassium oxide – K2O | < 0.02 |

| Manganese oxide – MnO | < 0.02 |

| Physical and mechanical properties | |

| Density | 2.65 g/cm³ |

| Hardness | 6.5 – 7 Mohs |

Explanations on hardness data

General material specification:

Material: sintered corundum 1 - 99.7 % Al2O3

Abrasion resistance: fairly good

Suitable for: medium-hard, fibrous samples

| General specifications | |

| Material | Sintered corundum 1 – Al2O3 |

| ISO/EN/DIN code | |

| Chemical composition | |

| Element | Share % |

| Aluminium oxide – Al2O3 | 99.651 |

| Silicon oxide – SiO2 | 0.257 |

| Calcium oxide – CaO | 0.081 |

| Other | 0.011 |

| Physical and mechanical properties | |

| Density | 3.8 g/cm³ |

| Hardness | 18.000N/mm² (Vickers HV 0.5) |

Explanations on hardness data

General material specification:

Material: silicon nitride - Si3N4

Abrasion resistance: excellent

Suitable for: abrasive samples, metal-free grinding

| General specifications | |

| Material | Silicon nitride - Si3N4 |

| ISO/EN/DIN code | SNCB5 |

| Chemical composition | |

| Element | Share % |

| Al2 O3 Y2 O3 | 12.5 |

| Si3 N4 | 86.5 |

| Other | 1.00 |

| Physical and mechanical properties | |

| Density | 3.25 g/cm³ |

| Hardness | 91.1 HRA |

Explanations on hardness data

General material specification:

Material: zirconium oxide - ZrO2

Abrasion resistance: very good

Suitable for: fibrous, abrasive samples

| General specifications | |

| Material | Zirconium oxide - ZrO2 |

| Chemical composition | |

| Element | Share % |

| Zirconium oxide – ZrO2 | 94.2 - 95.2 |

| Hafnium oxide – HfO2 | 1 - 2 |

| Magnesium oxide – MgO | 3.5 |

| Silicon dioxide – SiO | 0.1 |

| Aluminium oxide – Al2O3 | 0.1 |

| Other | 0.1 |

| Physical and mechanical properties | |

| Density | 5.7 g/cm³ |

| Hardness Vickers | 1200 (HV10) |

Explanations on hardness data

General material specification:

Material: hardened, stainless steel - Fe-Cr

Abrasion resistance: good

Suitable for: medium-hard, brittle samples

| General specifications | |

| Material | hardened stainless steel – 1.4125 |

| ISO/EN/DIN code | X105CrMo17 |

| Chemical composition | |

| Element | Share % |

| Iron– Fe | 81.4 |

| Chromium – Cr | 17 |

| Carbon – C | 1.1 |

| Molybdenum – Mo | 0.5 |

| Physical and mechanical properties | |

| Density | 7.7 kg/dm³ |

| Hardness | ~ 60 HRC |

Explanations on hardness data

General material specification:

Material: hardmetal tungsten carbide - WC

Abrasion resistance: very good

Suitable for: hard, abrasive samples

| General specifications | |

| Material | Tungsten carbide - WC |

| ISO/EN/DIN code | |

| Chemical composition | |

| Element | Share % |

| Tungsten carbide – TC | 88 |

| Cobalt – Co | 12 |

| Physical and mechanical properties | |

| Density | 14.3 g/cm³ |

| Hardness | 89.7 HRA |

Explanations on hardness data

GRINDING BALLS 10 MM DIAMETER FOR GRINDING BOWL 500 ML, 250 ML, 80 ML

General material specification:

Material: agate - SiO2

Abrasion resistance: good

Suitable for: soft to medium-hard sample

Grinding balls made of agate with 10 mm dia. are also recommended as sieving aid for dry sieving of material with a high proportion of fine particles.

Recommended number per sieve: 10 pieces.

| General specifications | |

| Material | Agate – SiO2 |

| Chemical composition | |

| Element | Share % |

| Silicon oxide– SiO2 | 99.9 |

| Aluminium – Al2O3 | < 0.02 |

| Iron oxide – Fe2O3 | < 0.02 |

| Calcium oxide – CaO | < 0.02 |

| Magnesium oxide – MgO | < 0.02 |

| Sodium oxide – Na2O | < 0.02 |

| Potassium oxide – K2O | < 0.02 |

| Manganese oxide – MnO | < 0.02 |

| Physical and mechanical properties | |

| Density | 2.65 g/cm³ |

| Hardness | 6.5 – 7 Mohs |

Explanations on hardness data

General material specification:

Material: sintered corundum 1 - 99.7 % Al2O3

Abrasion resistance: fairly good

Suitable for: medium-hard, fibrous samples

| General specifications | |

| Material | Sintered corundum 1 – Al2O3 |

| ISO/EN/DIN code | |

| Chemical composition | |

| Element | Share % |

| Aluminium oxide – Al2O3 | 99.651 |

| Silicon oxide – SiO2 | 0.257 |

| Calcium oxide – CaO | 0.081 |

| Other | 0.011 |

| Physical and mechanical properties | |

| Density | 3.8 g/cm³ |

| Hardness | 18.000N/mm² (Vickers HV 0.5) |

Explanations on hardness data

General material specification:

Material: silicon nitride - Si3N4

Abrasion resistance: excellent

Suitable for: abrasive samples, metal-free grinding

| General specifications | |

| Material | Silicon nitride - Si3N4 |

| ISO/EN/DIN code | SNCB5 |

| Chemical composition | |

| Element | Share % |

| Al2 O3 Y2 O3 | 12.5 |

| Si3 N4 | 86.5 |

| Other | 1.00 |

| Physical and mechanical properties | |

| Density | 3.25 g/cm³ |

| Hardness | 91.1 HRA |

Explanations on hardness data

General material specification:

Material: zirconium oxide - ZrO2

Abrasion resistance: very good

Suitable for: fibrous, abrasive samples

| General specifications | |

| Material | Zirconium oxide - ZrO2 |

| Chemical composition | |

| Element | Share % |

| Zirconium oxide – ZrO2 | 94.2 - 95.2 |

| Hafnium oxide – HfO2 | 1 - 2 |

| Magnesium oxide – MgO | 3.5 |

| Silicon dioxide – SiO | 0.1 |

| Aluminium oxide – Al2O3 | 0.1 |

| Other | 0.1 |

| Physical and mechanical properties | |

| Density | 5.7 g/cm³ |

| Hardness Vickers | 1200 (HV10) |

Explanations on hardness data

General material specification:

Material: hardened, stainless steel - Fe-Cr

Abrasion resistance: good

Suitable for: hard, medium-hard, brittle samples

| General specifications | |

| Material | hardened stainless steel – 1.4125 |

| ISO/EN/DIN code | X105CrMo17 |

| Chemical composition | |

| Element | Share % |

| Iron– Fe | 81.4 |

| Chromium – Cr | 17 |

| Carbon – C | 1.1 |

| Molybdenum – Mo | 0.5 |

| Physical and mechanical properties | |

| Density | 7.7 kg/dm³ |

| Hardness | ~ 60 HRC |

Explanations on hardness data

General material specification:

Material: hardmetal tungsten carbide - WC

Abrasion resistance: very good

Suitable for: hard, abrasive samples

| General specifications | |

| Material | Tungsten carbide - WC |

| ISO/EN/DIN code | |

| Chemical composition | |

| Element | Share % |

| Tungsten carbide – TC | 88 |

| Cobalt – Co | 12 |

| Physical and mechanical properties | |

| Density | 14.3 g/cm³ |

| Hardness | 89.7 HRA |

Explanations on hardness data

GRINDING BALLS 5 MM DIAMETER FOR GRINDING BOWL 500 ML, 250 ML, 80 ML

General material specification:

Material: agate - SiO2

Abrasion resistance: good

Suitable for: soft to medium-hard sample

100 grinding balls made of agate with 5 mm dia. weigh approx. 17 g. With the weight information, the high number of balls per grinding bowl can be determined by weighing.

Grinding balls made of agate with 5 mm dia. are also recommended as sieving aid for dry sieving of material with a high proportion of fine particles.

Recommended number per sieve: 15 pieces.

| General specifications | |

| Material | Agate – SiO2 |

| Chemical composition | |

| Element | Share % |

| Silicon oxide– SiO2 | 99.9 |

| Aluminium – Al2O3 | < 0.02 |

| Iron oxide – Fe2O3 | < 0.02 |

| Calcium oxide – CaO | < 0.02 |

| Magnesium oxide – MgO | < 0.02 |

| Sodium oxide – Na2O | < 0.02 |

| Potassium oxide – K2O | < 0.02 |

| Manganese oxide – MnO | < 0.02 |

| Physical and mechanical properties | |

| Density | 2.65 g/cm³ |

| Hardness | 6.5 – 7 Mohs |

Explanations on hardness data

General material specification:

Material: zirconium oxide - ZrO2

Abrasion resistance: very good

Suitable for: fibrous, abrasive samples

100 grinding balls made of zirconium oxide with 5 mm dia. weigh approx. 38 g.

With the weight information, the high number of balls per grinding bowl can be determined by weighing.

| General specifications | |

| Material | Zirconium oxide ZrO2 |

| ISO/EN/DIN code | |

| Chemical composition | |

| Element | Share % |

| Zirconium oxide - ZrO2 | 95% |

| Yttrium oxide -Y2O3 | 5% |

| Physical and mechanical properties | |

| Density | 6.0 g/cm³ |

| Hardness Vickers | 1300 (HV10) |

Explanations on hardness data

General material specification:

Material: hardened, stainless steel - Fe-Cr

Abrasion resistance: good

Suitable for: hard, medium-hard, brittle samples

100 grinding balls made of hardened, stainless steel with 5 mm dia. weigh approx. 52 g.

With the weight information, the high number of balls per grinding bowl can be determined by weighing.

| General specifications | |

| Material | hardened stainless steel – 1.4125 |

| ISO/EN/DIN code | X105CrMo17 |

| Chemical composition | |

| Element | Share % |

| Iron– Fe | 81.4 |

| Chromium – Cr | 17 |

| Carbon – C | 1.1 |

| Molybdenum – Mo | 0.5 |

| Physical and mechanical properties | |

| Density | 7.7 kg/dm³ |

| Hardness | ~ 60 HRC |

Explanations on hardness data

General material specification:

Material: hardmetal tungsten carbide - WC

Abrasion resistance: very good

Suitable for: hard, abrasive samples

100 grinding balls made of hardmetal tungsten carbide with 5 mm dia. weigh approx. 97 g. With the weight information, the high number of balls per grinding bowl can be determined by weighing.

| General specifications | |

| Material | Tungsten carbide - WC |

| ISO/EN/DIN code | |

| Chemical composition | |

| Element | Share % |

| Tungsten carbide – TC | 88 |

| Cobalt – Co | 12 |

| Physical and mechanical properties | |

| Density | 14.3 g/cm³ |

| Hardness | 89.7 HRA |

Explanations on hardness data

GRINDING BALLS ≤ 3 MM DIAMETER FOR GRINDING BOWL 500 ML, 250 ML, 80 ML (100 G PACKAGE)

General material specification:

Material: zirconium oxide - ZrO2

Abrasion resistance: very good

Suitable for: fibrous, abrasive samples

Grinding balls made of zirconium oxide with 3 mm dia. are packed in 100 g units and must be weight out.

In the selection aid you can find the required mass per grinding bowl.

| General specifications | |

| Material | Zirconium oxide ZrO2 |

| ISO/EN/DIN code | |

| Chemical composition | |

| Element | Share % |

| Zirconium oxide - ZrO2 | 95% |

| Yttrium oxide -Y2O3 | 5% |

| Physical and mechanical properties | |

| Density | 6.0 g/cm³ |

| Hardness Vickers | 1300 (HV10) |

Explanations on hardness data

General material specification:

Material: zirconium oxide - ZrO2

Abrasion resistance: very good

Suitable for: fibrous, abrasive samples

Grinding balls made of zirconium oxide with 2 mm dia. are packed in 100 g units and must be weight out. In the selection aid you can find the required mass per grinding bowl.

| General specifications | |

| Material | Zirconium oxide ZrO2 |

| ISO/EN/DIN code | |

| Chemical composition | |

| Element | Share % |

| Zirconium oxide - ZrO2 | 95% |

| Yttrium oxide -Y2O3 | 5% |

| Physical and mechanical properties | |

| Density | 6.0 g/cm³ |

| Hardness Vickers | 1300 (HV10) |

Explanations on hardness data

General material specification:

Material: zirconium oxide - ZrO2

Abrasion resistance: very good

Suitable for: fibrous, abrasive samples

Grinding balls made of zirconium oxide with 1.5 mm dia. are packed in 100 g units and must be weight out.

In the selection aid you can find the required mass per grinding bowl.

| General specifications | |

| Material | Zirconium oxide ZrO2 |

| ISO/EN/DIN code | |

| Chemical composition | |

| Element | Share % |

| Zirconium oxide - ZrO2 | 95% |

| Yttrium oxide -Y2O3 | 5% |

| Physical and mechanical properties | |

| Density | 6.0 g/cm³ |

| Hardness Vickers | 1300 (HV10) |

Explanations on hardness data

General material specification:

Material: zirconium oxide - ZrO2

Abrasion resistance: very good

Suitable for: fibrous, abrasive samples

Grinding balls made of zirconium oxide with 1 mm dia. are packed in 100 g units and must be weight out. In the selection aid you can find the required mass per grinding bowl.

| General specifications | |

| Material | Zirconium oxide ZrO2 |

| ISO/EN/DIN code | |

| Chemical composition | |

| Element | Share % |

| Zirconium oxide - ZrO2 | 95% |

| Yttrium oxide -Y2O3 | 5% |

| Physical and mechanical properties | |

| Density | 6.0 g/cm³ |

| Hardness Vickers | 1300 (HV10) |

Explanations on hardness data

General material specification:

Material: zirconium oxide - ZrO2

Abrasion resistance: very good

Suitable for: fibrous, abrasive samples

Grinding balls made of zirconium oxide with 0.5 mm dia. are packed in 100 g units and must be weight out.

In the selection aid you can find the required mass per grinding bowl.

| General specifications | |

| Material | Zirconium oxide ZrO2 |

| ISO/EN/DIN code | |

| Chemical composition | |

| Element | Share % |

| Zirconium oxide - ZrO2 | 95% |

| Yttrium oxide -Y2O3 | 5% |

| Physical and mechanical properties | |

| Density | 6.0 g/cm³ |

| Hardness Vickers | 1300 (HV10) |

Explanations on hardness data

General material specification:

Material: zirconium oxide - ZrO2

Abrasion resistance: very good

Suitable for: fibrous, abrasive samples

Grinding balls made of zirconium oxide with 0.1 mm dia. are packed in 100 g units and must be weight out.

In the selection aid you can find the required mass per grinding bowl.

| General specifications | |

| Material | Zirconium oxide ZrO2 |

| ISO/EN/DIN code | |

| Chemical composition | |

| Element | Share % |

| Zirconium oxide - ZrO2 | 95% |

| Yttrium oxide -Y2O3 | 5% |

| Physical and mechanical properties | |

| Density | 6.0 g/cm³ |

| Hardness Vickers | 1300 (HV10) |

Explanations on hardness data

General material specification:

Material: hardened, stainless steel - Fe-Cr

Abrasion resistance: good

Suitable for: hard, medium-hard, brittle samples

Grinding balls made of hardened, stainless steel with 3 mm dia. are packed in 100 g units and must be weight out.

In the selection aid you can find the required mass per grinding bowl.

| General specifications | |

| Material | hardened stainless steel – 1.4125 |

| ISO/EN/DIN code | X105CrMo17 |

| Chemical composition | |

| Element | Share % |

| Iron– Fe | 81.4 |

| Chromium – Cr | 17 |

| Carbon – C | 1.1 |

| Molybdenum – Mo | 0.5 |

| Physical and mechanical properties | |

| Density | 7.7 kg/dm³ |

| Hardness | ~ 60 HRC |

Explanations on hardness data

General material specification:

Material: hardened, stainless steel - Fe-Cr

Abrasion resistance: good

Suitable for: hard, medium-hard, brittle samples

Grinding balls made of hardened, stainless steel with 1 mm dia. are packed in 100 g units and must be weight out.

In the selection aid you can find the required mass per grinding bowl.

| General specifications | |

| Material | hardened stainless steel – 1.4125 |

| ISO/EN/DIN code | X105CrMo17 |

| Chemical composition | |

| Element | Share % |

| Iron– Fe | 81.4 |

| Chromium – Cr | 17 |

| Carbon – C | 1.1 |

| Molybdenum – Mo | 0.5 |

| Physical and mechanical properties | |

| Density | 7.7 kg/dm³ |

| Hardness | ~ 60 HRC |

Explanations on hardness data

General material specification:

Material: hardmetal tungsten carbide - WC

Abrasion resistance: very good

Suitable for: hard, abrasive samples

Grinding balls made of hardmetal tungsten carbide with 3 mm dia. are packed in 100 g units and must be weight out.

In the selection aid you can find the required mass per grinding bowl.

| General specifications | |

| Material | Tungsten carbide - WC |

| ISO/EN/DIN code | |

| Chemical composition | |

| Element | Share % |

| Tungsten carbide – TC | 88 |

| Cobalt – Co | 12 |

| Physical and mechanical properties | |

| Density | 14.3 g/cm³ |

| Hardness | 89.7 HRA |

Explanations on hardness data

General material specification:

Material: hardmetal tungsten carbide - WC

Abrasion resistance: very good

Suitable for: hard, abrasive samples

Grinding balls made of hardmetal tungsten carbide with 1.6 mm dia. are packed in 100 g units and must be weight out.

In the selection aid you can find the required mass per grinding bowl.

| General specifications | |

| Material | Tungsten carbide - WC |

| ISO/EN/DIN code | |

| Chemical composition | |

| Element | Share % |

| Tungsten carbide – TC | 88 |

| Cobalt – Co | 12 |

| Physical and mechanical properties | |

| Density | 14.3 g/cm³ |

| Hardness | 89.7 HRA |

Explanations on hardness data

General material specification:

Material: hardmetal tungsten carbide - WC

Abrasion resistance: very good

Suitable for: hard, abrasive samples

Grinding balls made of hardmetal tungsten carbide with 0.6 mm dia. are packed in 100 g units and must be weight out.

In the selection aid you can find the required mass per grinding bowl.

| General specifications | |

| Material | Tungsten carbide - WC |

| ISO/EN/DIN code | |

| Chemical composition | |

| Element | Share % |

| Tungsten carbide – TC | 88 |

| Cobalt – Co | 12 |

| Physical and mechanical properties | |

| Density | 14.3 g/cm³ |

| Hardness | 89.7 HRA |

Explanations on hardness data

SPECIAL ACCESSORIES

The EASY GTM classic line Gas Pressure and Temperature Measuring System: continuous measurement of gas pressure and temperature directly in the grinding bowl, turns the Planetary Mills PULVERISETTE 5 and PULVERISETTE 6 of the FRITSCH classic line into analytical measuring systems.

For quickly and safely grinding in inert gas and for mechanical alloying classic line gassing lids are recommended.

Certificate for IQ/OQ documentation is also available.

EASY GTM - GAS PRESSURE AND TEMPERATURE MEASURING SYSTEM

EASY GTM classic line gas pressure and temperature measuring system, incl. 250 ml grinding bowl made of hardened, stainless steel with special lid, transmitter, separate receiver and software EasyGTMControl.

For continuous measurement of gas pressure and temperature for PULVERISETTE 5 and PULVERISETTE 6 classic line.

Due to the continuous measurement of gas pressure and temperature, thermal effects as well as physical and chemical reactions or pressure variations can be monitored directly in the grinding bowl. For this, simply insert the grinding bowl with the radio transmitter integrated in the lid, without any modification to the mill itself. The monitored data is transmitted to a computer via a receiver. The EASY GTMControl software included in the scope of delivery generates a graphical presentation of the measured values, which can also be offered as a PDF report and transferred to an Excel™ table.

The measurement of the grinding bowl temperature allows an integral statement on the process variable temperature, which takes account of the effects of all friction, impact and transformation processes. The continuous and highly sensitive measurement of the gas pressure in the grinding bowl enables the detection of very rapid reactions. The measured gas pressure describes, among other things, the interactions of the gas with the surfaces created during grinding (adsorption and desorption of gases). Extremely rapid phase formations can be observed for the first time IN SITU as an adiabatic process without heat exchange with the system.

The EASY GTM-System provides valuable information:

• Investigations in the area of mechanical alloying for the production of new amorphous and nano-crystalline materials

• Monitoring and optimisation of grinding processes in industrial applications

Technical Data

• Temperature measurement range of the transmitter component: –40 to 110 °C

• Resolution of pressure signal: 1 mbar

• Permissible pressure in the grinding bowl: 0 – 20 bar – measuring range up to 30 bar

• Operating time with fully charged battery: approx. ½ year continuous operation (depending on operating temperature)

• Radio transmission: 2.4 GHz standard

If further grinding bowls and transmitters are needed, please ask for the respective order numbers.

EASY GTM classic line gas pressure and temperature measuring system, incl. 500 ml grinding bowl made of hardened, stainless steel with special lid, transmitter, separate receiver and software EasyGTMControl.

For continuous measurement of gas pressure and temperature for PULVERISETTE 5 and PULVERISETTE 6 classic line.

Due to the continuous measurement of gas pressure and temperature, thermal effects as well as physical and chemical reactions or pressure variations can be monitored directly in the grinding bowl. For this, simply insert the grinding bowl with the radio transmitter integrated in the lid, without any modification to the mill itself. The monitored data is transmitted to a computer via a receiver. The EASY GTMControl software included in the scope of delivery generates a graphical presentation of the measured values, which can also be offered as a PDF report and transferred to an Excel™ table.

The measurement of the grinding bowl temperature allows an integral statement on the process variable temperature, which takes account of the effects of all friction, impact and transformation processes. The continuous and highly sensitive measurement of the gas pressure in the grinding bowl enables the detection of very rapid reactions. The measured gas pressure describes, among other things, the interactions of the gas with the surfaces created during grinding (adsorption and desorption of gases). Extremely rapid phase formations can be observed for the first time IN SITU as an adiabatic process without heat exchange with the system.

The EASY GTM-System provides valuable information:

• Investigations in the area of mechanical alloying for the production of new amorphous and nano-crystalline materials

• Monitoring and optimisation of grinding processes in industrial applications

TECHNICAL DATA

• Temperature measurement range of the transmitter component: –40 to 110 °C

• Resolution of pressure signal: 1 mbar

• Permissible pressure in the grinding bowl: 0 – 20 bar – measuring range up to 30 bar

• Operating time with fully charged battery: approx. ½ year continuous operation (depending on operating temperature)

• Radio transmission: 2.4 GHz standard

If further grinding bowls and transmitters are needed, please ask for the respective order numbers.

ACCESSORIES FOR GRINDING IN INERT GAS AND FOR MECHANICAL ALLOYING - GASSING LID WITH VALVES AND SEAL RING FOR GRINDING BOWL 500 ML VOLUME

Gassing lid agate with steel casing with 2 valves and seal ring.

Through the use of this special lid (incl. seal ring) on an agate grinding bowl with 500 ml volume, the grinding bowl can be used for grinding with inert gas and mechanical alloying.

Two valves allow for easy and safe filling of the bowls with inert gas, while they are firmly clamped in the mill. A special additional Lock-System is required for gas-tight removal and transportation: order no. 90.1400.00.

Gassing lids with Swagelok valves are available on request.

| General specifications | |

| Material | Agate – SiO2 |

| Chemical composition | |

| Element | Share % |

| Silicon oxide– SiO2 | 99.9 |

| Aluminium – Al2O3 | < 0.02 |

| Iron oxide – Fe2O3 | < 0.02 |

| Calcium oxide – CaO | < 0.02 |

| Magnesium oxide – MgO | < 0.02 |

| Sodium oxide – Na2O | < 0.02 |

| Potassium oxide – K2O | < 0.02 |

| Manganese oxide – MnO | < 0.02 |

| Physical and mechanical properties | |

| Density | 2.65 g/cm³ |

| Hardness | 6.5 – 7 Mohs |

Explanations on hardness data

Gassing lid silicon nitride with with steel casing with 2 valves and seal ring.

Through the use of this special lid (incl. seal ring) on a silicon nitride grinding bowl with 500 ml volume, the grinding bowl can be used for grinding with inert gas and mechanical alloying.

Two valves allow for easy and safe filling of the bowls with inert gas, while they are firmly clamped in the mill. A special additional Lock-System is required for gas-tight removal and transportation: order no. 90.1400.00.

Gassing lids with Swagelok valves are available on request.

| General specifications | |

| Material | Silicon nitride - Si3N4 |

| ISO/EN/DIN code | SNCB5 |

| Chemical composition | |

| Element | Share % |

| Al2 O3 Y2 O3 | 9 |

| Si3 N4 | 91 |

| Physical and mechanical properties | |

| Density | 3.25 g/cm³ |

| Hardness | 91.1 HRA |

Explanations on hardness data

Gassing lid zirconium oxide with 2 valves and seal ring.

Through the use of this special lid (incl. seal ring) on a zirconium oxide grinding bowl with 500 ml volume, the grinding bowl can be used for grinding with inert gas and mechanical alloying.

Two valves allow for easy and safe filling of the bowls with inert gas, while they are firmly clamped in the mill. A special additional Lock-System is required for gas-tight removal and transportation: order no. 90.1400.00.

Gassing lids with Swagelok valves are available on request.

| General specifications | |

| Material | Zirconium oxide - ZrO2 |

| Chemical composition | |

| Element | Share % |

| Zirconium oxide – ZrO2 | 94.2 - 95.2 |

| Hafnium oxide – HfO2 | 1 - 2 |

| Magnesium oxide – MgO | 3.5 |

| Silicon dioxide – SiO | 0.1 |

| Aluminium oxide – Al2O3 | 0.1 |

| Other | 0.1 |

| Physical and mechanical properties | |

| Density | 5.7 g/cm³ |

| Hardness Vickers | 1200 (HV10) |

Explanations on hardness data

Gassing lid hardened, stainless steel with 2 valves and seal ring.

Through the use of this special lid (incl. seal ring) on a hardened, stainless steel grinding bowl with 500 ml volume, the grinding bowl can be used for grinding with inert gas and mechanical alloying.

Two valves allow for easy and safe filling of the bowls with inert gas, while they are firmly clamped in the mill. A special additional Lock-System is required for gas-tight removal and transportation: order no. 90.1400.00.

Gassing lids with Swagelok valves are available on request.

| General specifications | |

| Material | hardened stainless steel – 1.4125 |

| ISO/EN/DIN code | X105CrMo17 |

| Chemical composition | |

| Element | Share % |

| Iron– Fe | 81.4 |

| Chromium – Cr | 17 |

| Carbon – C | 1.1 |

| Molybdenum – Mo | 0.5 |

| Physical and mechanical properties | |

| Density | 7.7 kg/dm³ |

| Hardness | ~ 60 HRC |

Explanations on hardness data

Replacement seal ring made of Viton for gassing lid, for agate grinding bowls with 500 ml volume.

Replacement seal ring made of Viton for gassing lids, for all other grinding bowls with 500 ml volume.

ACCESSORIES FOR GRINDING IN INERT GAS AND FOR MECHANICAL ALLOYING - GASSING LID WITH VALVES AND SEAL RING FOR GRINDING BOWL 250 ML VOLUME

Gassing lid agate with steel casing with 2 valves and seal ring.

Through the use of this special lid (incl. seal ring) on an agate grinding bowl with 250 ml and 80 ml volume, the grinding bowl can be used for grinding with inert gas and mechanical alloying.

Two valves allow for easy and safe filling of the bowls with inert gas, while they are firmly clamped in the mill. A special additional Lock-System is required for gas-tight removal and transportation: order no. 90.1400.00.

Gassing lids with Swagelok valves are available on request.

| General specifications | |

| Material | Agate – SiO2 |

| Chemical composition | |

| Element | Share % |

| Silicon oxide– SiO2 | 99.9 |

| Aluminium – Al2O3 | < 0.02 |

| Iron oxide – Fe2O3 | < 0.02 |

| Calcium oxide – CaO | < 0.02 |

| Magnesium oxide – MgO | < 0.02 |

| Sodium oxide – Na2O | < 0.02 |

| Potassium oxide – K2O | < 0.02 |

| Manganese oxide – MnO | < 0.02 |

| Physical and mechanical properties | |

| Density | 2.65 g/cm³ |

| Hardness | 6.5 – 7 Mohs |

Explanations on hardness data

Gassing lid silicon nitride with with steel casing with 2 valves and seal ring.

Through the use of this special lid (incl. seal ring) on an silicon nitride grinding bowl with 250 ml volume, the grinding bowl can be used for grinding with inert gas and mechanical alloying.

Two valves allow for easy and safe filling of the bowls with inert gas, while they are firmly clamped in the mill. A special additional Lock-System is required for gas-tight removal and transportation: order no. 90.1400.00.

Gassing lids with Swagelok valves are available on request.

| General specifications | |

| Material | Silicon nitride - Si3N4 |

| ISO/EN/DIN code | SNCB5 |

| Chemical composition | |

| Element | Share % |

| Al2 O3 Y2 O3 | 9 |

| Si3 N4 | 91 |

| Physical and mechanical properties | |

| Density | 3.25 g/cm³ |

| Hardness | 91.1 HRA |

Explanations on hardness data

Gassing lid zirconium oxide with with steel casing with 2 valves and seal ring.

Through the use of this special lid (incl. seal ring) on a zirconium oxide grinding bowl with 250 ml volume, the grinding bowl can be used for grinding with inert gas and mechanical alloying.

Two valves allow for easy and safe filling of the bowls with inert gas, while they are firmly clamped in the mill. A special additional Lock-System is required for gas-tight removal and transportation: order no. 90.1400.00.

Gassing lids with Swagelok valves are available on request.

| General specifications | |

| Material | Zirconium oxide - ZrO2 |

| Chemical composition | |

| Element | Share % |

| Zirconium oxide – ZrO2 | 94.2 - 95.2 |

| Hafnium oxide – HfO2 | 1 - 2 |

| Magnesium oxide – MgO | 3.5 |

| Silicon dioxide – SiO | 0.1 |

| Aluminium oxide – Al2O3 | 0.1 |

| Other | 0.1 |

| Physical and mechanical properties | |

| Density | 5.7 g/cm³ |

| Hardness Vickers | 1200 (HV10) |

Explanations on hardness data

Gassing lid hardened, stainless steel with 2 valves and seal ring.

Through the use of this special lid (incl. seal ring) on a hardened, stainless steel grinding bowl with 250 ml volume, the grinding bowl can be used for grinding with inert gas and mechanical alloying.

Two valves allow for easy and safe filling of the bowls with inert gas, while they are firmly clamped in the mill. A special additional Lock-System is required for gas-tight removal and transportation: order no. 90.1400.00.

Gassing lids with Swagelok valves are available on request.

| General specifications | |

| Material | hardened stainless steel – 1.4125 |

| ISO/EN/DIN code | X105CrMo17 |

| Chemical composition | |

| Element | Share % |

| Iron– Fe | 81.4 |

| Chromium – Cr | 17 |

| Carbon – C | 1.1 |

| Molybdenum – Mo | 0.5 |

| Physical and mechanical properties | |

| Density | 7.7 kg/dm³ |

| Hardness | ~ 60 HRC |

Explanations on hardness data

Gassing lid hardmetal tungsten with steel casing with 2 valves and seal ring.

Through the use of this special lid (incl. seal ring) on a hardmetal tungsten carbide grinding bowl with 250 ml volume, the grinding bowl can be used for grinding with inert gas and mechanical alloying.

Two valves allow for easy and safe filling of the bowls with inert gas, while they are firmly clamped in the mill. A special additional Lock-System is required for gas-tight removal and transportation: order no. 90.1400.00.

Gassing lids with Swagelok valves are available on request.

| General specifications | |

| Material | Tungsten carbide - WC |

| ISO/EN/DIN code | |

| Chemical composition | |

| Element | Share % |

| Tungsten carbide – TC | 88 |

| Cobalt – Co | 12 |

| Physical and mechanical properties | |

| Density | 14.3 g/cm³ |

| Hardness | 89.7 HRA |

Explanations on hardness data

Replacement seal ring made of Vitonfor gassing lids for agate grinding bowls classic line 250 ml + 80 ml volume.

Replacement seal ring made of Viton for gassing lid for grinding bowls silicon nitride bowls 250 ml volume.

Replacement seal ring made of Viton for gassing lids for all other grinding bowls classic line with 250 ml volume.

ACCESSORIES FOR GRINDING IN INERT GAS AND FOR MECHANICAL ALLOYING - GASSING LID WITH VALVES AND SEAL RING FOR GRINDING BOWL 80 ML VOLUME

Gassing lid agate with steel casing with 2 valves and seal ring.

Through the use of this special lid (incl. seal ring) on an agate grinding bowl with 250 ml and 80 ml volume, the grinding bowl can be used for grinding with inert gas and mechanical alloying.

Two valves allow for easy and safe filling of the bowls with inert gas, while they are firmly clamped in the mill. A special additional Lock-System is required for gas-tight removal and transportation: order no. 90.1400.00.

Gassing lids with Swagelok valves are available on request.

| General specifications | |

| Material | Agate – SiO2 |

| Chemical composition | |

| Element | Share % |

| Silicon oxide– SiO2 | 99.9 |

| Aluminium – Al2O3 | < 0.02 |

| Iron oxide – Fe2O3 | < 0.02 |

| Calcium oxide – CaO | < 0.02 |

| Magnesium oxide – MgO | < 0.02 |

| Sodium oxide – Na2O | < 0.02 |

| Potassium oxide – K2O | < 0.02 |

| Manganese oxide – MnO | < 0.02 |

| Physical and mechanical properties | |

| Density | 2.65 g/cm³ |

| Hardness | 6.5 – 7 Mohs |

Explanations on hardness data

Gassing lid zirconium oxide with 2 valves and seal ring.

Through the use of this special lid (incl. seal ring) on a zirconium oxide grinding bowl with 80 ml volume, the grinding bowl can be used for grinding with inert gas and mechanical alloying.

Two valves allow for easy and safe filling of the bowls with inert gas, while they are firmly clamped in the mill. A special additional Lock-System is required for gas-tight removal and transportation: order no. 90.1400.00.

Gassing lids with Swagelok valves are available on request.

| General specifications | |

| Material | Zirconium oxide - ZrO2 |

| Chemical composition | |

| Element | Share % |

| Zirconium oxide – ZrO2 | 94.2 - 95.2 |