Otros Rotor / Beater Mills

OTROS GRUPOS DE PRODUCTOS

Cross Beater Mill - stainless steel grinding insert

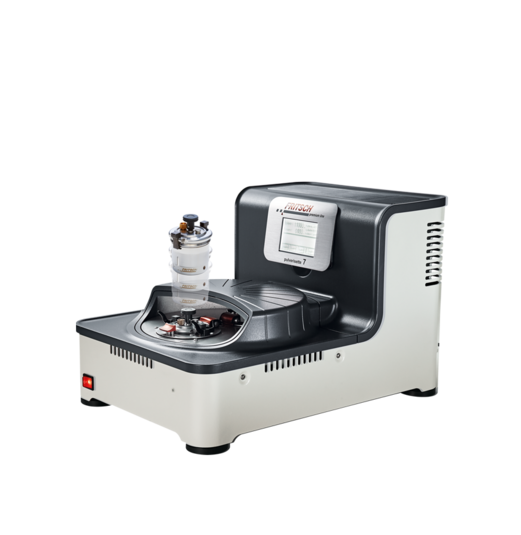

PULVERISETTE 16

The Cross Beater Mill PULVERISETTE 16 is equipped with a grinding insert, cross beater and impact plates made of stainless steel. A 5 litre collecting vessel with filter hose is also included.

Also available are bottom sieves made of stainless steel in various sizes and perforations and for the comminution of large quantities a special 30 litre collecting vessel with filter hose.

The element analysis for grinding insert, cross beater and impact plates are found here

Please note: For this FRITSCH mill, you require at least one bottom sieve.

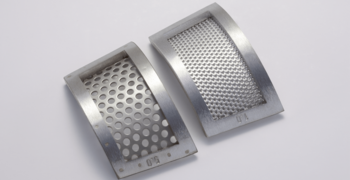

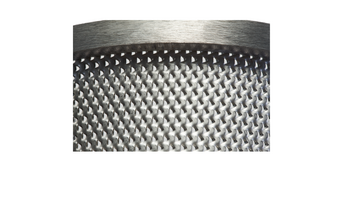

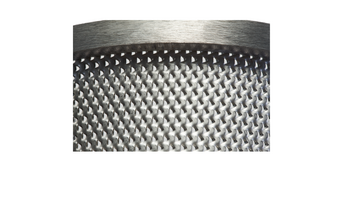

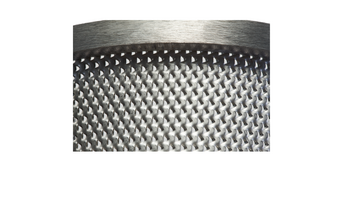

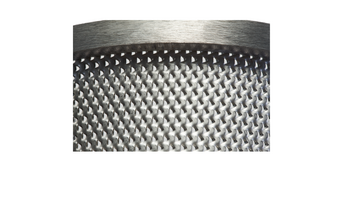

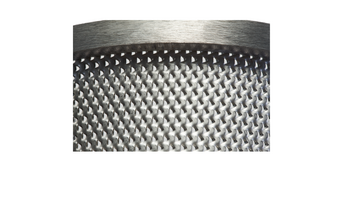

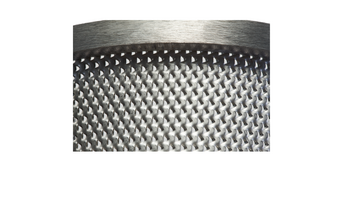

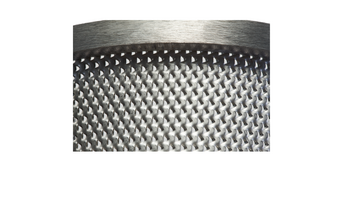

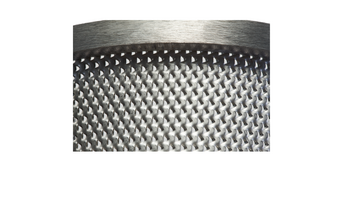

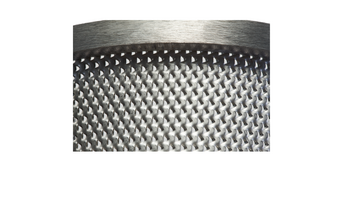

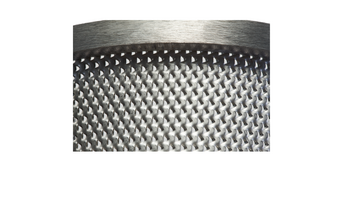

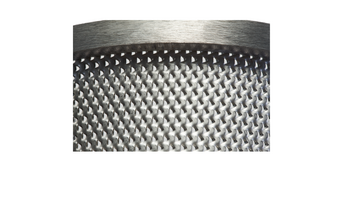

BOTTOM SIEVES made of stainless steel 316L

For the PULVERISETTE 16 are bottom sieves made of stainless steel either in trapezoidal or round perforations in various sizes available. In general, the finer the desired final fineness, the smaller the perforation of the bottom sieve should be; the larger the perforation, the higher the throughput.

BOTTOM SIEVES MADE OF STAINLESS STEEL 316L

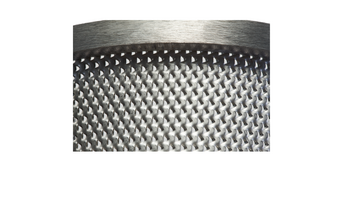

The bottom sieves are made of stainless steel trapezoidal resp. round perforation sheets of metal. Larger openings mean faster throughput, less time in the mill and less wear.

Bottom sieves with trapezoidal perforation offer an improved size reduction through extra shearing action. Bottom sieves with round perforation are recommended for size reduction of brittle material of medium fineness with smaller grain width band.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

The bottom sieves are made of stainless steel trapezoidal resp. round perforation sheets of metal. Larger openings mean faster throughput, less time in the mill and less wear.

Bottom sieves with trapezoidal perforation offer an improved size reduction through extra shearing action. Bottom sieves with round perforation are recommended for size reduction of brittle material of medium fineness with smaller grain width band.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

The bottom sieves are made of stainless steel trapezoidal resp. round perforation sheets of metal. Larger openings mean faster throughput, less time in the mill and less wear.

Bottom sieves with trapezoidal perforation offer an improved size reduction through extra shearing action. Bottom sieves with round perforation are recommended for size reduction of brittle material of medium fineness with smaller grain width band.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

The bottom sieves are made of stainless steel trapezoidal resp. round perforation sheets of metal. Larger openings mean faster throughput, less time in the mill and less wear.

Bottom sieves with trapezoidal perforation offer an improved size reduction through extra shearing action. Bottom sieves with round perforation are recommended for size reduction of brittle material of medium fineness with smaller grain width band.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

The bottom sieves are made of stainless steel trapezoidal resp. round perforation sheets of metal. Larger openings mean faster throughput, less time in the mill and less wear.

Bottom sieves with trapezoidal perforation offer an improved size reduction through extra shearing action. Bottom sieves with round perforation are recommended for size reduction of brittle material of medium fineness with smaller grain width band.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

The bottom sieves are made of stainless steel trapezoidal resp. round perforation sheets of metal. Larger openings mean faster throughput, less time in the mill and less wear.

Bottom sieves with trapezoidal perforation offer an improved size reduction through extra shearing action. Bottom sieves with round perforation are recommended for size reduction of brittle material of medium fineness with smaller grain width band.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

The bottom sieves are made of stainless steel trapezoidal resp. round perforation sheets of metal. Larger openings mean faster throughput, less time in the mill and less wear.

Bottom sieves with trapezoidal perforation offer an improved size reduction through extra shearing action. Bottom sieves with round perforation are recommended for size reduction of brittle material of medium fineness with smaller grain width band.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

The bottom sieves are made of stainless steel trapezoidal resp. round perforation sheets of metal. Larger openings mean faster throughput, less time in the mill and less wear.

Bottom sieves with trapezoidal perforation offer an improved size reduction through extra shearing action. Bottom sieves with round perforation are recommended for size reduction of brittle material of medium fineness with smaller grain width band.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

The bottom sieves are made of stainless steel trapezoidal resp. round perforation sheets of metal. Larger openings mean faster throughput, less time in the mill and less wear.

Bottom sieves with trapezoidal perforation offer an improved size reduction through extra shearing action. Bottom sieves with round perforation are recommended for size reduction of brittle material of medium fineness with smaller grain width band.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

The bottom sieves are made of stainless steel trapezoidal resp. round perforation sheets of metal. Larger openings mean faster throughput, less time in the mill and less wear.

Bottom sieves with trapezoidal perforation offer an improved size reduction through extra shearing action. Bottom sieves with round perforation are recommended for size reduction of brittle material of medium fineness with smaller grain width band.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

The bottom sieves are made of stainless steel trapezoidal resp. round perforation sheets metal. Larger openings mean faster throughput, less time in the mill and less wear.

Bottom sieves with trapezoidal perforation offer an improved size reduction through extra shearing action. Bottom sieves with round perforation are recommended for size reduction of brittle material of medium fineness with smaller grain width band.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

The bottom sieves are made of stainless steel trapezoidal resp. round perforation sheets of metal. Larger openings mean faster throughput, less time in the mill and less wear.

Bottom sieves with trapezoidal perforation offer an improved size reduction through extra shearing action. Bottom sieves with round perforation are recommended for size reduction of brittle material of medium fineness with smaller grain width band.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

The bottom sieves are made of stainless steel trapezoidal resp. round perforation sheets of metal. Larger openings mean faster throughput, less time in the mill and less wear.

Bottom sieves with trapezoidal perforation offer an improved size reduction through extra shearing action. Bottom sieves with round perforation are recommended for size reduction of brittle material of medium fineness with smaller grain width band.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

The bottom sieves are made of stainless steel trapezoidal resp. round perforation sheets of metal. Larger openings mean faster throughput, less time in the mill and less wear.

Bottom sieves with trapezoidal perforation offer an improved size reduction through extra shearing action. Bottom sieves with round perforation are recommended for size reduction of brittle material of medium fineness with smaller grain width band.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

The bottom sieves are made of stainless steel trapezoidal resp. round perforation sheets of metal. Larger openings mean faster throughput, less time in the mill and less wear.

Bottom sieves with trapezoidal perforation offer an improved size reduction through extra shearing action. Bottom sieves with round perforation are recommended for size reduction of brittle material of medium fineness with smaller grain width band.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Bottom sieves made of chromium-free steel DC01Cu for heavy-metal-free grinding

The bottom sieves are made of chromium-free steel DC01Cu trapezoidal resp. round perforation sheets of metal. Larger openings mean faster throughput, less time in the mill and less wear.

Bottom sieves with trapezoidal perforation offer an improved size reduction through extra shearing action. Bottom sieves with round perforation are recommended for size reduction of brittle material of medium fineness with smaller grain width band.

The bottom sieves are made of chromium-free steel DC01Cu trapezoidal resp. round perforation sheets of metal. Larger openings mean faster throughput, less time in the mill and less wear.

Bottom sieves with trapezoidal perforation offer an improved size reduction through extra shearing action. Bottom sieves with round perforation are recommended for size reduction of brittle material of medium fineness with smaller grain width band.

The bottom sieves are made of chromium-free steel DC01Cu trapezoidal resp. round perforation sheets of metal. Larger openings mean faster throughput, less time in the mill and less wear.

Bottom sieves with trapezoidal perforation offer an improved size reduction through extra shearing action. Bottom sieves with round perforation are recommended for size reduction of brittle material of medium fineness with smaller grain width band.

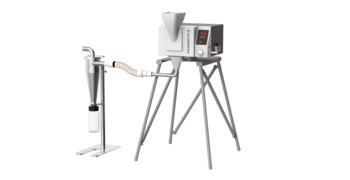

Sample exhaustion with Cyclone separator

The combination of the Cross Beater Mill with the high-performance Cyclone separator enable a simple cleaning and feeding, the use of finer bottom sieves for achieving a higher final fineness, increases the throughput and reduces the thermal load of the samples – even for materials, which are otherwise difficult to grind. Select Cyclone separator and accessories.

High-performance Cyclone separator

The FRITSCH high-performance Cyclone separator completely made of stainless steel 316L is indispensable in many industries. Due to its high surface quality, it offers enhanced resistance to corrosive media such as alkalis and acids and is especially easy to clean with a wide range of possible cleaning agents, without leaving any residues. The comminuted sample is drawn into a screwed-on collecting vessel or in a smaller sample glass, in which it can also be transported and stored. In addition, it can be completely dismantled, fully emptied, flooded and sterilised, and thus offers reliable protection against cross-contamination.

The advantages of the high-performance Cyclone separator at a glance

- Faster throughput

- Improved discharge of material from the grinding chamber

- Additional strong cooling of the grinding material and grinding parts

- Efficient size reduction of temperature-sensitive samples, electrostatically-charged plastics or powder coatings

- Ideal for light materials, small sample quantities and finer sieve sizes

- Highly efficient continuous comminution of large quantities

| General specifications | |

| Material | Stainless steel – 1.4301 |

| ISO/EN/DIN code | X5CrNi1810 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 66.805 |

| Carbon – C | 0.070 |

| Silicon – Si | 1.000 |

| Manganese – Mn | 2.000 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.030 |

| Chromium – Cr | 19.5 |

| Nickel – Ni | 10.5 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 7.8 g/cm³ |

| Hardness | HRB 96 |

Explanations on hardness data

Collecting Vessels for High-performance Cyclone separator

Sample glass 1 litre for sample exhaustion with the high-performance Cyclone separator.

The sample glass with 2 litres volume is recommended for sample exhaustion with the high-performance Cyclone separator for sample discharges larger than 1000 ml, since only a 1 litre sample glass is included in the delivery of the high-performance Cyclone separator.

The sample glass with 5 litres volume is recommended for sample exhaustion with the high-performance Cyclone separator for sample discharges larger than 1000 ml, since only a 1 litre sample glass is included in the delivery of the high-performance Cyclone separator.

The collecting vessel 20 litres is recommended for sample exhaustion with the high-performance Cyclone separator for sample discharges larger than 1000 ml, since only a 1 litre sample glass is included in the delivery of the high-performance Cyclone separator.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

The collecting vessel 60 litres is recommended for sample exhaustion with the high-performance Cyclone separator for sample discharges larger than 1000 ml, since only a 1 litre sample glass is included in the delivery of the high-performance Cyclone separator.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Exhaust system for High-performance Cyclone separator

The exhaust system, dust category "M" according to DIN EN 60335-2-69 for 230 V/1~, 50/60 Hz, 1600 Watt is versatile:

For combination with the high performance and small volume cyclones.

To operate the FRITSCH Cyclones you need an exhaust system. The strong airflow ensures simple feeding, increases throughput, and reduces the thermal load of the samples. The high performance and small volume Cyclone separator can be combined with Universal Cutting Mills PULVERISETTE 19, the Variable Speed Rotor Mill PULVERISETTE 14 premium line and classic line. The small volume cyclone can also be combined with the Variable Speed Rotor Mill PULVERISETE 14 premium line and classic line even for passive utilisation – without sample exhaust.

The high-performance cyclone is ideal for combination with the Universal Cutting Mills PULVERISETTE 19 large, the Cross Beater Mill PULVERISETTE 16 and the Disk Mill PULVERISETTE 13 premium line for optimal sample extraction and for comminution of larger quantities.

For cooling of the Variable Speed Rotor Mill PULVERISETTE 14 premium line

By connecting the exhaust system with the connecting piece order no. 14.8128.00, the cooling of the mill can easily be enhanced.

For connecting to Disk Mill PULVERISETTE 13 premium line

The exhaust is simply connected to the PULVERISETTE 13 premium line and operated via a start and stop button on the instrument – for dust free comminution.

For connecting to the Jaw Crusher PULVERISETTE 1, Modell I + II classic line

Simply connect the exhaust system to the integrated connection of the PULVERISETTE 1. Fine dust arising during comminution is automatically removed. The exhaust system is also very useful when cleaning the grinding parts.

For connecting to the Disk Mill PULVERISETTE 13 classic line

The exhaust system can be easily connected to the PULVERISETTE 13 classic line. Fine dust arising during comminution is automatically removed. The exhaust system is also very useful when cleaning the grinding parts.

For exhaustion of the sample during dry measurement with the Laser Particle Sizers ANALYSETTE 22 NeXT

An exhaust system is necessary to ensure automatic sample exhaustion during dry measurement. When the measurement is completed it can also be easily used to manually clean the feeder.

Please note that the exhaust system article no. 43.9070.00, is not equipped with a fine filter and therefore dust may escape. Please consider the valid occupational health and safety regulations. This exhaust system is mostly recommended for dust-free grinding and the vacuuming of during the process developing fine dust in the upper part of the grinding chamber and for the cleaning of the grinding parts.

For vacuuming of the sample during dry measurement with the Laser Particle Sizers ANALYSETTE 22 NeXT, we recommended we recommend the exhaust system article no. 43.9060.00, which is equipped with a hose and an ultra-fine filter of dust class "H" according to DIN EN 60335-2-69, so that the escape of fine dust is reduced.

1 pack = 5 pieces

One pack is included in the scope of delivery of the exhaust system (article No. 43.9070.00).

These fleece filter bags should be used for the vacuuming off of fine, dry materials.

For the vacuuming off of coarse, wet materials are plastic bags available (article no. 43.9052.00).

1 pack = 5 pieces

One pack is included in the order of the exhaust system (article No. 43.9070.00).

These plastic bags should be used for the vacuuming off of coarse, wet materials.

For the vacuuming off of fine, dry materials are paper filter bags available (article no. 43.9055.00).

FURTHER ACCESSORIES

The standard equipment delivered with the PULVERISETTE 16 includes a cloth filter hose between the mill and the 5 litre collecting vessel that ensures a constant airflow in the grinding chamber; accelerates the throughput and prevents blockages – for fast, gentle comminution.

We also offer a 30 litre collecting vessel for grinding larger quantities.

Combine your PULVERISETTE 16 with a support stand for a stand-alone instrument that you can place anywhere. A certificate for IQ/OQ documentation is also available.

UNIVERSAL SUPPORT STAND AND COLLECTING VESSEL

Stand for free installation of the following devices:

Universal Cutting Mill PULVERISETTE 19 variable speed 300-3000 rpm

Universal Cutting Mill PULVERISETTE 19 variable speed 50-700 rpm

Universal Cutting Mill PULVERISETTE 19 variable speed 50-700 rpm large

Universal Cutting Mill PULVERISETTE 19 variable speed 300-3000 rpm Large

Cross Beater Mill PULVERISETTE 16 with grinding insert made of cast iron

Cross Beater Mill PULVERISETTE 16 with grinding insert made of stainless steel

The PULVERISETTE 19 is shown as an example in the photo.

As standard the PULVERISETTE 16 is delivered with a collecting vessel 5 litres. For grinding large quantities this collecting vessel with a capacity of 26 litres and filter hose is recommended.

IQ/OQ documentation (questionnaire format - implementation by customer) for the independent utilization for the support of instrument qualification in the quality management system for the Cross Beater Mill PULVERISETTE 16.