Potentes y robustos

Los trituradores de mandíbula son ideales para la trituración previa de materiales muy duros, duros, semiduros, quebradizos, viscosos y sensibles a la temperatura. La muestra se tritura ejerciendo una elevada presión entre una mandíbula fija y otra móvil.

Para evitar el molesto desgaste, las herramientas de molienda se presentan en acero de diferentes durezas, metal duro de carburo de tungsteno y óxido de circonio.

-

Versátiles - Trituradores de mandíbula classic line

El pre-triturador compacto

- Trituración rápida y uniforme

- Granulometría final 1–15 mm, rendimiento hasta 200kg/h

- Limpieza sencilla y fácil

- Sistema de retirada de mandíbulas sencillo

- Espacio ajustable de 10 etapas entre las mandíbulas trituradoras

- Operación segura y libre de polvo

- Cinemática de mandíbulas variable para una granulometría final más fina

- Acceso a la tolva particularmente rápido y sencillo, es fácil y rápido de llenar y de limpiar

BÚSQUEDA DE PRODUCTO

2 Resultados

Details

PULVERISETTE 1

classic line

- Max. feed size (depends on material)

- 60 mm

- Max. continuous throughput

- 140 kg/h

- Final fineness (depends on gap adjustment)

- 1 - 15 mm

- Power consumption

- 1.7 kW

Details

PULVERISETTE 1

classic line

- Max. feed size (depends on material)

- 95 mm

- Max. continuous throughput

- 200 kg/h

- Final fineness (depends on gap adjustment)

- 1 - 15 mm

- Power consumption

- 2.6 kW

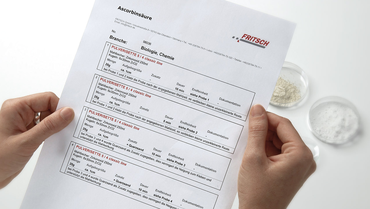

Descargas

Prospecto de Trituradores de mandíbulas y Molinos de discos classic line

para Triturador de mandíbulas PULVERISETTE 1 classic line, Molino de discos PULVERISETTE 13 classic line, Molino de discos oscilantes PULVERISETTE 9 y Prensa de comprimidos