Virtual Product Presentation

With the virtual product presentation you can experience our products for milling, sizing, sieving and dividing directly at your workplace.

Flexibles y robustos

El programa de molinos de corte FRITSCH ofrece exactamente la solución adecuada para cada campo de aplicación: como modelo estándar para la mayoría de aplicaciones típicas, fuerte y potente para material más duro y como novedad ahora también con un amplio espectro de velocidades de giro para un empleo universal. Todos los modelos se caracterizan por una trituración especialmente rápida y segura, y por una limpieza inigualablemente rápida y sencilla.

Los molinos a cuchillas son ideales para triturar materiales blandos y semiduros, quebradizos, fibrosos, resistentes y sensibles a la temperatura, así como plásticos y también para la preparación de mezclas heterogéneas. Las muestras se trituran por corte y cizallamiento, mientras que el casete de tamizado determina la granulometría deseada.

Las diferentes geometrías de cuchilla y la intercambiabilidad de cuchillas y contracuchillas aseguran la máxima flexibilidad y durabilidad. Para controlar la resistencia a la abrasión se pueden utilizar herramientas de corte tanto de acero de diversos tipos como también de metal duro de carburo de wolframio.

-

PULVERISETTE 19 - Completamente en acero inoxidable

El molino de corte universal PULVERISETTE 19 se suministra ahora por completo en acero inoxidable

- ideal para materiales blandos, semiduros, duros, quebradizos, duros, elásticos, fibrosos y sensibles a la temperatura

- especial para el ámbito analítico y las industrias alimentaria y farmaceútica

- versión completamente en acero resistente a la corrosión 316L

- mayor resistencia a los medios corrosivos como los álcalis y los ácidos

- limpieza y manejo sencillos

- Los materiales cumplen con las directrices de la industria alimentaria y farmacéutica

- combinable con FRITSCH el separador ciclónico de alto rendimiento y con el de pequeñas cantidades de, para una aspiración óptima de muestras

-

Ideas patentadas para trabajar mejor

Nuestros molinos albergan gran cantidad de ideas FRITSCH patentadas, cada una inspirada en el trabajo de nuestros clientes, desarrollada por motivaciones prácticas y optimizada para aplicaciones prácticas. Convierten el uso diario en una actividad simple y eficiente y ofrecen ventajas que marcan la diferencia entre los molinos de corte de FRITSCH y otras marcas.

- diseño patentado: con cámara de molienda de apertura completa y tapa totalmente extraíble, para una limpieza rápida y sin residuos.

- doble alojamiento cónico patentado del rotor: permite un funcionamiento estable con desgaste mínimo en los modelos PULVERISETTE 19 y PULVERISETTE 19 large.

- casete de tamizado patentado: en los modelos PULVERISETTE 19 y PULVERISETTE 19 large asegura siempre una distancia óptima al rotor y su colocación es especialmente rápida y sencilla.

- combinación patentada: de molino a cuchillas y aspiración de muestras con los separadores ciclónicos FRITSCH para los modelos PULVERISETTE 19 o la combinación de molinos a cuchillas P19 large/P-19.

NEW: MINI CUTTING MILL PULVERISETTE 29!

The inexpensive cutting mill for small sample quantities - especially suitable for preparing samples of grains, other seeds or plastics.

BÚSQUEDA DE PRODUCTO

- Max. feed size (depends on material and funnel)

- 70 x 80 mm

- Max. throughput (depends on material and sieve cassette)

- 60 l/h

- Final fineness (depends on sieve cassette)

- 0.1 - 20 mm

- Rotor speed (depends on voltage and frequency)

- 300 - 3000 rpm

- Max. feed size (depends on material and funnel)

- 70 x 80 mm

- Max. throughput (depends on material and sieve cassette)

- 60 l/h

- Final fineness (depends on sieve cassette)

- 0.1 - 20 mm

- Rotor speed (depends on voltage and frequency)

- 50 - 700 rpm

- Max. feed size (depends on material and funnel)

- up to 25 mm

- Max. throughput (depends on material and sieve cassette)

- Final fineness (depends on sieve cassette)

- 0.25 - 6 mm

- Rotor speed (depends on voltage and frequency)

- 500-6000 rpm

- Max. feed size (depends on material and funnel)

- 70 x 70 mm

- Max. throughput (depends on material and sieve cassette)

- 50 l/h

- Final fineness (depends on sieve cassette)

- 0.25 - 20 mm

- Rotor speed (depends on voltage and frequency)

- 2800/3400 rpm

- Max. feed size (depends on material and funnel)

- 120 x 85 mm

- Max. throughput (depends on material and sieve cassette)

- 85 l/h

- Final fineness (depends on sieve cassette)

- 0.25 - 20 mm

- Rotor speed (depends on voltage and frequency)

- 50 - 700 rpm

- Max. feed size (depends on material and funnel)

- 120 x 85 mm

- Max. throughput (depends on material and sieve cassette)

- 85 l/h

- Final fineness (depends on sieve cassette)

- 0.25 - 20 mm

- Rotor speed (depends on voltage and frequency)

- 300-3000 rpm

- Max. feed size (depends on material and funnel)

- 120 x 85 mm

- Max. throughput (depends on material and sieve cassette)

- 60 l/h

- Final fineness (depends on sieve cassette)

- 0.1 - 20 mm

- Rotor speed (depends on voltage and frequency)

- 50-700 - resp. 300-3000 rpm

Descargas

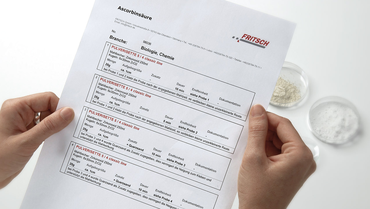

Product Profile P-29

Product Profile P-19

Prospecto de Molinos a cuchillas

para Molino de corte PULVERISETTE 15, Molinos de corte universales PULVERISETTE 19 y Combinación de corte