Otros Disk Mills

OTROS GRUPOS DE PRODUCTOS

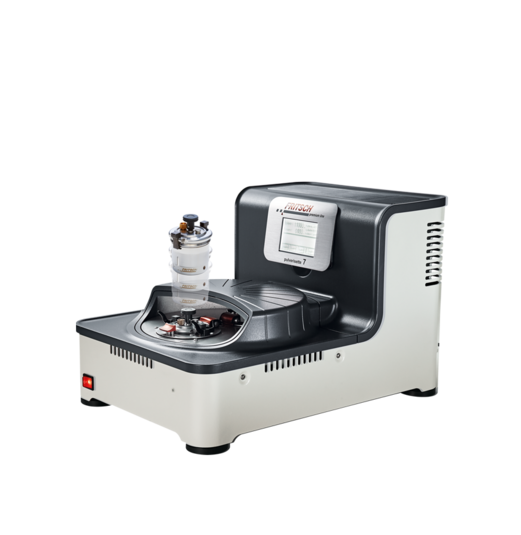

Disk Mill

PULVERISETTE 13

classic line

Detalles del producto

Technical Data

| Working principle | shearing |

| Optimal for material type | very hard, hard-abrasive, hard-brittle, medium-hard samples and for metal-free grinding |

| Grinding tools | fixed and movable grinding disk |

| Materials of the grinding tools | hardened steel cast, manganese steel, hardmetal tungsten carbide, zirconium oxide |

| Max. feed size (depending on the material) | 20 mm |

| Min. sample quantity | 20 - 30 ml |

| Max. throughput (depends on material) | 150 kg/h |

| Final fineness | 0.1 - 12 mm |

| Feeding | batchwise/ continuous |

| Collecting drawer | 1.9 l volume |

| Rotating speed | grinding disk 440 rpm |

| Bearings | needle and double row angular contact ball bearings |

| Electrical Details* | 400 V/3~, 50 Hz, 1790 watt |

| Instrument also available in the following voltage (other voltages on request) | 200 V/3~, 60 Hz, 2100 watt order no. 13.1020.00 |

| Emission sound pressure level at the workplace according to DIN EN ISO 3746 (depending on the material to be ground) | approx. LpAd = 81 dB |

| Weight | 140 kg |

| Dimensions (W x D x H) | bench top instrument 44 x 87 x 40 cm |

*The three-phase AC version„/3~“ is definitely preferable over a single-phase version „/1~“, since you obtain with the three-phase AC version more power, better effectiveness and a greater energy efficiency.

Please note: the three-phase AC version „/3~“ must always be operated on a three-phase supply network.

High final fineness in minimum time

Below are examples listed – always in reference to 1 kg feed quantity and 20 mm particle size and arranged by material types from hard to medium-hard.

Orientation guide for materials and instruments settings

| Material to be ground | Grinding time | Gap setting | Fineness (µm) | Throughput | |

| (min) | (mm) | 90% < x |

50% < x |

(kg/h) | |

| Basalt | 2.1 3.5 |

1.0 0.1 |

220 |

600 60 |

28 17 |

| Clinker | 2.0 10.0 |

0.5 0.1 |

900 220 |

450 60 |

30 6 |

| Slate | 1.4 2.2 |

1.0 0.1 |

300 |

1500 90 |

45 27 |

| Hard coal | 3.5 13.5 |

1.0 0.1 |

250 |

800 100 |

17 4 |

| Limestone | 2.0 6.3 |

1.0 0.1 |

1000 210 |

420 100 |

30 10 |

| Thomas meal (potash) | 1.3 2.3 |

1.0 0.5 |

1000 350 |

350 150 |

45 26 |

| Pumice stone | 3.5 5.0 |

0.5 0.1 |

600 150 |

250 30 |

17 12 |

| Glass | 2.5 3.3 3.8 |

3.0 2.0 1.0 |

4000 2500 1400 |

2240 1600 800 |

25 18 16 |

Please note

| The indicated results are to be considered as an orientation guide, since the chemical and physical properties (e.g. residual moisture, morphology, etc.) can vary even with the same material to be ground. |