Otros Cutting Mills

OTROS GRUPOS DE PRODUCTOS

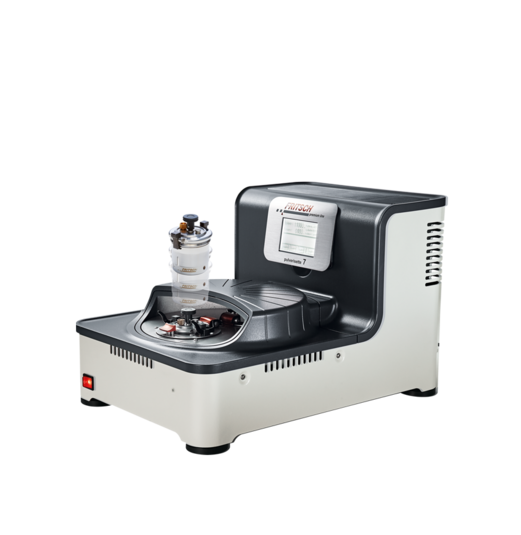

Cutting Mill Combination

PULVERISETTE 19 large / PULVERISETTE 19

-

OVERVIEW

Patented power team

With the extra powerful, patented FRITSCH Cutting Mill Combination of the Universal Cutting Mill PULVERISETTE 19 large with variable rotational speed of 50-700 rpm and the Universal Cutting Mill PULVERISETTE 19 with a variable rotational speed of 300-3000 rpm, as well as the associated FRITSCH high-performance Cyclone separator, it is possible, for example, to process 2 litres of sample material with a particle size of 30 mm in only one single step.

It doesn‘t matter how heterogeneous the sample is – even household waste, construction waste, German recycling system bales or light shredder fractions from automobile recycling: Within five minutes, our extra-powerful double mill will reduce any of these materials into a representatively divided analysis sample with a final fineness of < 500 μm! This is the ideal solution for inexpensive preparation of heterogeneous materials for analysis according to the Technical Instructions on Municipal Waste (TOC) or for determination of the calorific value and chlorine content. -

WORKING PRINCIPLE

Operating principles of the powerful FRITSCH Cutting Mill Combination

The extra powerful FRITSCH Cutting Mill Combination consists of the Universal Cutting Mill PULVERISETTE 19 large with variable rotational speed of 50-700 rpm and the Universal Cutting Mill PULVERISETTE 19 with a variable rotational speed of 300-3000 rpm. The entire sample is pre-crushed by the PULVERISETTE 19 large then falls automatically through a funnel into a sample divider which divides the sample according to a 1:13 ratio by default. The division ratio is variable.This smaller sample is then automatically comminuted in the PULVERISETTE 19 down to a final fineness of 0.2 mm and drawn into the collecting vessel by the connected FRITSCH high-performance Cyclone separator.

Through selection of the cutting tool sets and sieve cassettes, the FRITSCH Cutting Mill Combination can be individually adapted to any specific application. All accessories of the PULVERISETTE 19 large and PULVERISETTE 19 are available for this.

-

FEATURES

- Maximum feed size 120 x 85 mm

- Patented fully-automated two-stage comminution

- Defined final fineness due to interchangeable sieve cassettes 0.2 – 10 mm, (further sieve sizes available)

- Sample exhaustion via high-performance Cyclone separator in a collecting vessel 60 litres

- Integrated sample division to reduce quantity for fine size reduction

- Sample cooling during the comminution process

- Processing of sample material with moisture content up to 30 %

- Exceptionally high material throughput

- Cutting rotor and sieve cassette can be removed and replaced without tools

-

FRITSCH high-performance CYCLONE separator

The extra powerful FRITSCH high-performance Cyclone separator

The FRITSCH high-performance Cyclone separator completely made of stainless steel 304 is particularly indispensable in the analytical sector and in the food and pharmaceutical industries, and for the processing of heterogeneous mixtures of material, e.g. in the cement industry.

Due to its high surface quality, it offers enhanced resistance to corrosive media such as alkalis and acids and is especially easy to clean with a wide range of possible cleaning agents, without leaving any residues. In addition, it can be completely dismantled, fully emptied, flooded and sterilised, and thus offers reliable protection against cross-contamination. -

EQUIPMENT / ACCESSORIES

Standard equipment for the universal application

The FRITSCH Cutting Mill Combination consists of:consisting of: Universal Cutting Mill PULVERISETTE 19 large with variable rotational speed 50 to 700 rpm, Universal Cutting Mill PULVERISETTE 19 with variable rotational speed 300 to 3000 rpm, interposed sample divider, protected funnel with sample pusher, underframe, sample exhaustion with high-performance Cyclone separator made of stainless steel 304 with flexible tube connection, foodGrade, collecting vessel 60 litres as well as exhaust system For an individual adaptation to your specific application can the Cutting Mill Combination PULVERISETTE 19 large /19 be fitted with any type of cutting tool sets and sieve cassettes that are offered for the PULVERISETTE 19 large and PULVERISETTE 19.

View extensive accessories Universal Cutting Mill PULVERISETTE 19 large

View extensive accessories Universal Cutting Mill PULVERISETTE 19

-

Applications / Solutions

-

The manufacturing of cement is a very energy intensive production. Here for the most part coal is utilized as an energy carrier, but in the future the use of secondary fuels will increase and also the need of the analysis of such materials.

-

Sample preparation for the analysis of matured timber

The matured timber statute dedicates itself with the utilization and application of matured timber. A perfect assistant for the sample preparation are the FRITSCH Cutting Mills.

-

Análisis de muestras de combustibles secundarios en cementeras

Secondary fuel can be a very inhomogeneous sample, containing all types of polymers, paper, wood and low fractions of metal. Also recycled wood or parts of automobile tires might be used as secondary fuel. Before using it as fuel in the production of cement, several chemical analyses are necessary as quality control.

-