Otros Cutting Mills

OTROS GRUPOS DE PRODUCTOS

Cutting Mill

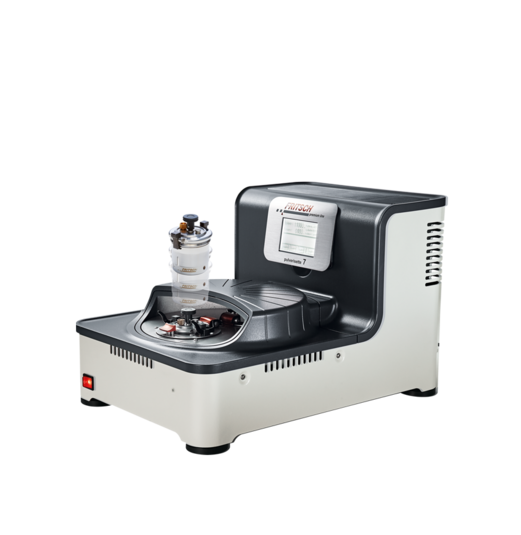

PULVERISETTE 15

-

OVERVIEW

For a wide range of common applications

The FRITSCH Cutting Mill PULVERISETTE 15 is ideal for the comminution of dry sample materials with soft to medium-hard consistency, for fibrous materials or cellulosic materials, as well as for sample preparation according to RoHS with a feed size of 70 x 70 mm and a throughput quantity of up to 50l/h. A cutting rotor speed of up to 3400 rpm ensures a high air throughput, fast processing and reproducible results.

The simple FRITSCH cleaning makes your work much easier. -

WORKING PRINCIPLE

Unique grinding chamber geometry

In Cutting Mills, the sample is comminuted according to the cutting principle of scissors, increasingly fine between the knives of the rotor and fixed knives until the desired final fineness is achieved.

Unique grinding chamber geometry: The grinding chamber is designed with minimal dead space and progressive cutting geometry between rotor and fixed knives. The sample material is continuously moved during comminution and cannot settle anywhere. In conjunctions with the special air flow, this is the basis for swift, blockage-free operation and fast cleaning without residue. -

FEATURES

- Fast, reproducible size reduction due to high cutting rotor speed of up to 3400 rpm

- Max. feed size 70 x 70 mm

- Throughput quantity of up to 50 l/h

- Defined final fineness replaceable sieve inserts 0.25 – 20 mm, (further sieve sizes available)

- Collecting vessel 3.5 litres or 60 litres

- Funnel for long- and bulk solids or protected funnel made of stainless steel with plastic sample pusher

- Housing and closing lid can be lifted to open completely – lid completely removable

- Externally adjustable cutting gap

- Rotor knives can be turned (2 cutting edges) – double service life

- Very stable: the rotor with double bearing on shaft and in the lid.

- Especially easy FRITSCH cleaning

- Optimum airflow for particularly fast size reduction and secure protection against clogging

- Extensive accessories for simplifying your daily work

-

EQUIPMENT / ACCESSORIES

Configure your Cutting Mill PULVERISETTE 15 exactly to your specific application

The Cutting Mill PULVERISETTE 15 is delivered without funnel, cutting tool set (consisting of rotors and fixed knives), sieve inserts, collection vessel and stand. Various funnels, collection vessels, rotors with fixed knives, sieve inserts and a support stand enable you to configure the Cutting Mill exactly for your application.

-

Applications / Solutions

-

During the processing of leather various chemical analyses have to be performed. Perfect for this task are the FRITSCH Cutting Mills.

-

Milling of leather for sample preparation

Leather is almost prepared in production facilities and also in testing institutes with cutting mills for analytical monitoring. Perfect for this task are the FRITSCH Cutting Mills.

-

Las nueces tienen que soportar mucho para el control de calidad

Routine quality inspections of nuts in production and trade are subject to clear regulatory requirements. The following article contains compact information about the requirements, as well as aspects of the sample preparation of nuts with FRITSCH cutting mills.

-

Straw, hay, dried plants, herbal teas - are mostly very bulky samples

An average shopping bag contains 300 g straw or expressed like this: 100 g of uncomminuted straw take up the space of 1 to 2 litres. These materials are very voluminous. For the comminution only a cutting mill with a high rotor speed can be considered.

-